- China is the world’s biggest market for industrial robots. It uses over 25% of global supply.

- China aims to become one of the top technological industrial nations in the next few years.

- Automation will affect 50 million factory workers in China.

Photo/Feng Xin

Robots will soon replace two-thirds of workers at Shanghai Cambridge Industries Group (CIG), an electronics manufacturer that produces Internet routers and modems for two out of every five Chinese households. This means that in less than two years, at least 1,400 workers like Wang Chunyan will have to find a new job.

CGTN reporter Feng Xi talks to Wang Chunyan, factory worker for CIG.

Like millions of migrant workers in China, 20-year-old Wang comes from a rural family in the country’s northwest. Working 12 hours per day, she earns about 4,000 yuan (575 US dollars) a month and pays 500 yuan for a small bedroom in a Shanghai suburb. Wang says she never thought about what she would do if robotic colleagues took over her job one day.

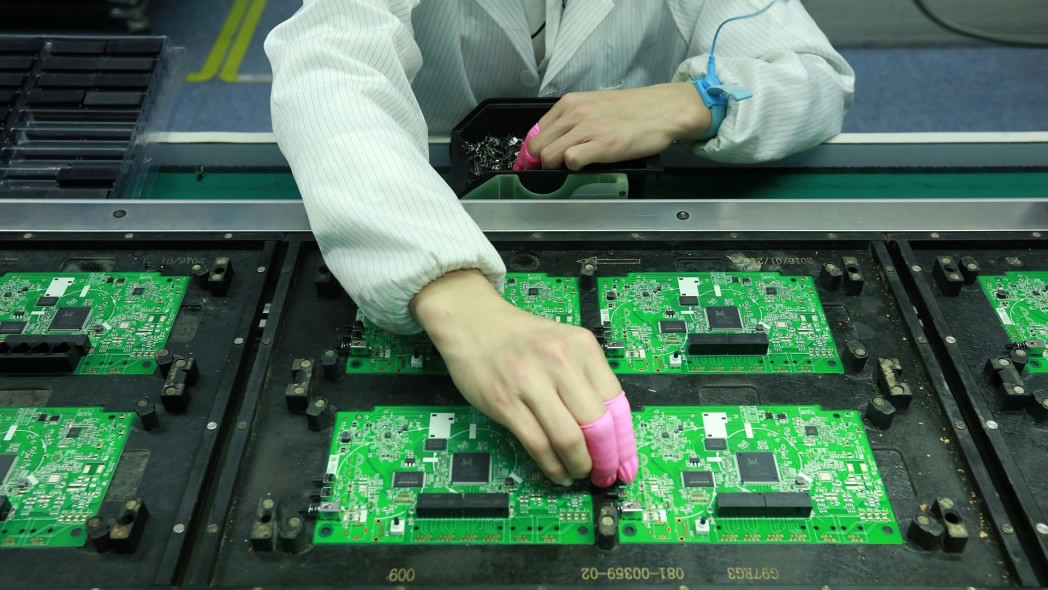

A worker inserts electronic parts into circuit boards by hand in CIG's factory in Shanghai. Photo/Feng Xin

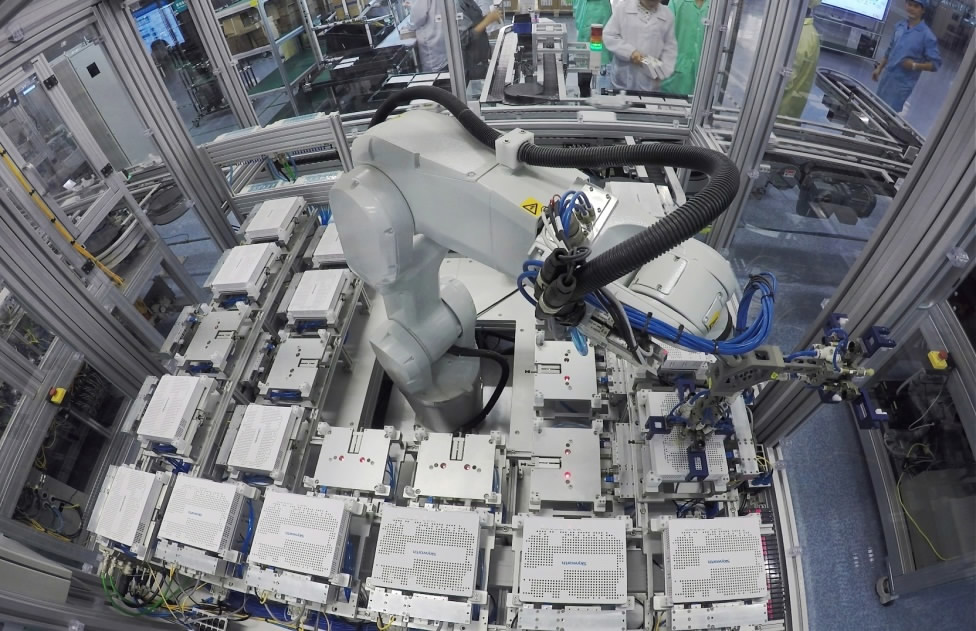

In this traditionally labor-intensive industry, most electronic parts have to be inserted into a circuit board by hand. It takes three seconds on average to insert one part. But now some of the work is done by robotic arms at CIG, three times faster than human hands.

Gerald Wong, CEO of Shanghai Cambridge Industries Group. Photo/Feng Xin

Such shifts to automation led the company’s CEO Gerald Wong to cut one third of his workforce in 2015 alone. The change came amid labor shortages and rising labor costs, he said.

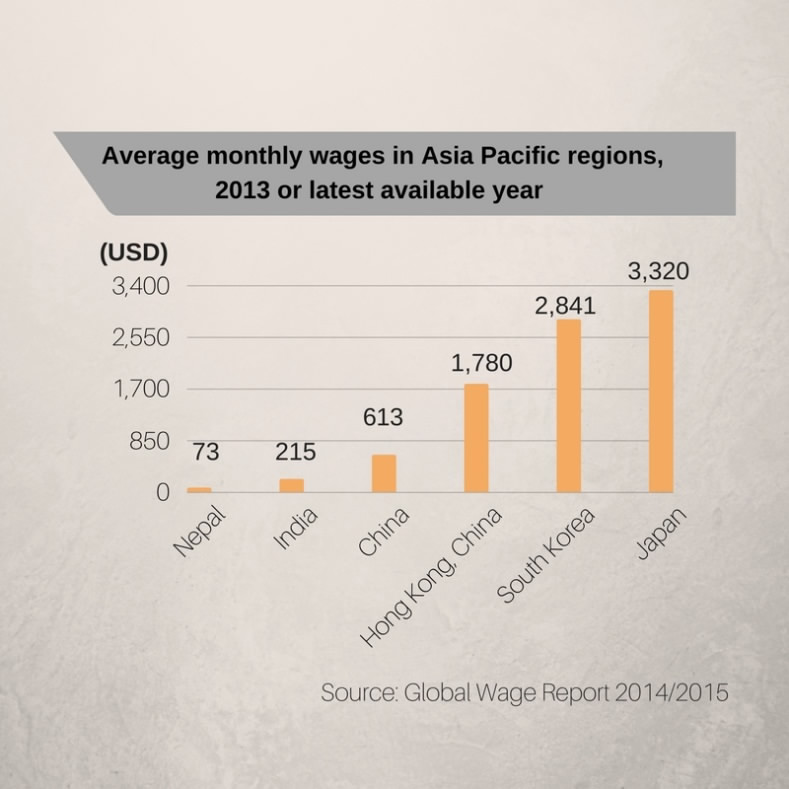

Chinese workers’ benefits and working conditions have largely improved in recent years, according to the 2015 Global Wage Report. Average wages were three times that of Indian workers and nearly 10 times that of Nepali workers, the report showed.

Workers in Shanghai also earn 1.5 times more than those in underdeveloped Chinese regions.

“People all came for China’s cheap labor, but this is coming to an end, especially in China’s Yangtze River Delta and Pearl River Delta,” said Wong.

“Everybody has realized the sweatshop is no longer working. It’s possible to move factories to China’s western regions or even Southeast Asia, but if you want to stay where you are, you have to shift to smart manufacturing,” he added.

Photo/Feng Xin

Smart manufacturing is much more than simply buying robots to replace humans, according to Wong. Collecting data, developing original software and producing supporting tools are more crucial to successful automation.

Figures from the International Federation of Robotics show that China was already the world’s biggest market for industrial robots in 2015, using more than a quarter of the global supply. With a national 10-year plan entitled “Made in China 2025,” the country is aiming to become one of the top technological industrial nations in just a few years.

Workers insert electronic parts into circuit boards by hand in CIG's factory in Shanghai. Photo/Feng Xin

But for 50 million Chinese manufacturing workers, the impact is unclear. Not every worker can turn into a technician or manager if he or she is replaced by a robot. So where can they go?

Photo/Feng Xin

Zhu Guirong started out as an ordinary worker at the Taiwan manufacturing giant Foxconn a decade ago. She's now the manager of an automatic production line. She believes that automation is inevitable in her industry.

“From a migrant worker’s point of view, I think we should be concerned for sure,” Zhu said. “Many people now face unemployment. Some might return to their hometowns. I think those who don’t think about it that much, might just wait and see. But those who have a lot of ideas might have already started expanding their options,” she said.

Some of the work is done by robotic arms at CIG in Shanghai. Photo/Feng Xin

Her boss Gerald Wong is even more ambitious, envisioning a “dark factory.” “When all production is automated, machines won’t need lights,” he said.

The day isn't far off for Wong’s factory to turn completely dark. But it will take time to see if robots will lead China’s manufacturing to a bright future.

(Story by CGTN's Feng Xin in Shanghai)

1086km