In recent years, major car companies across the world are shifting their supply system towards global sourcing and production, propelling the restructuring of the automotive and parts industry and forging closer cooperative ties among suppliers.

CGTN Photo

Challenges and risks

The supply chain has been plagued by an array of risks, including adverse weather, security problems, port congestion, facility failure, etc. Compounded by rising wages, unstable freight fees and volatile demands, the overall costs have seen substantial increase, according to CEVA Logistics.

Logistics operators are confronted with the challenge of how to make timely deliveries and manage inventory in the supply channel, which is critical for the flexibility of logistics operators.

In China, the impacts of ever-increasing wage are obvious. Low-cost manufacturing has relocated from coastal to hinterland provinces to save costs. Hon Hai Precision Industry Co., an electronic components manufacturer and exporter from Taiwan, which had been assembling iPhones and iPads in large quantities at Shenzhen factory, has retreated to hinterland cities such as Wuhan and Chengdu.

However, the supply chain is rather fragile in those far-flung areas. The transportation risks of export cargo will be heightened when the transit line is prolonged by thousands of miles, especially when the port cargo handling capacity is inadequate and the road toll is high.

China's automotive industry faces the challenges head on

Data from China Association of Automobile Manufacturers show that China has become the world's largest automobile producer and market for seven consecutive years.

A government research predicts that in the next 10 to 15 years, the automotive industry will contribute 16% to 17% to China's annual GDP growth.

Car companies are pursuing zero inventory in a bid to reduce management costs and respond to market demand promptly, which requires timely delivery underpinned by a well-managed supply chain, according to the Economist.

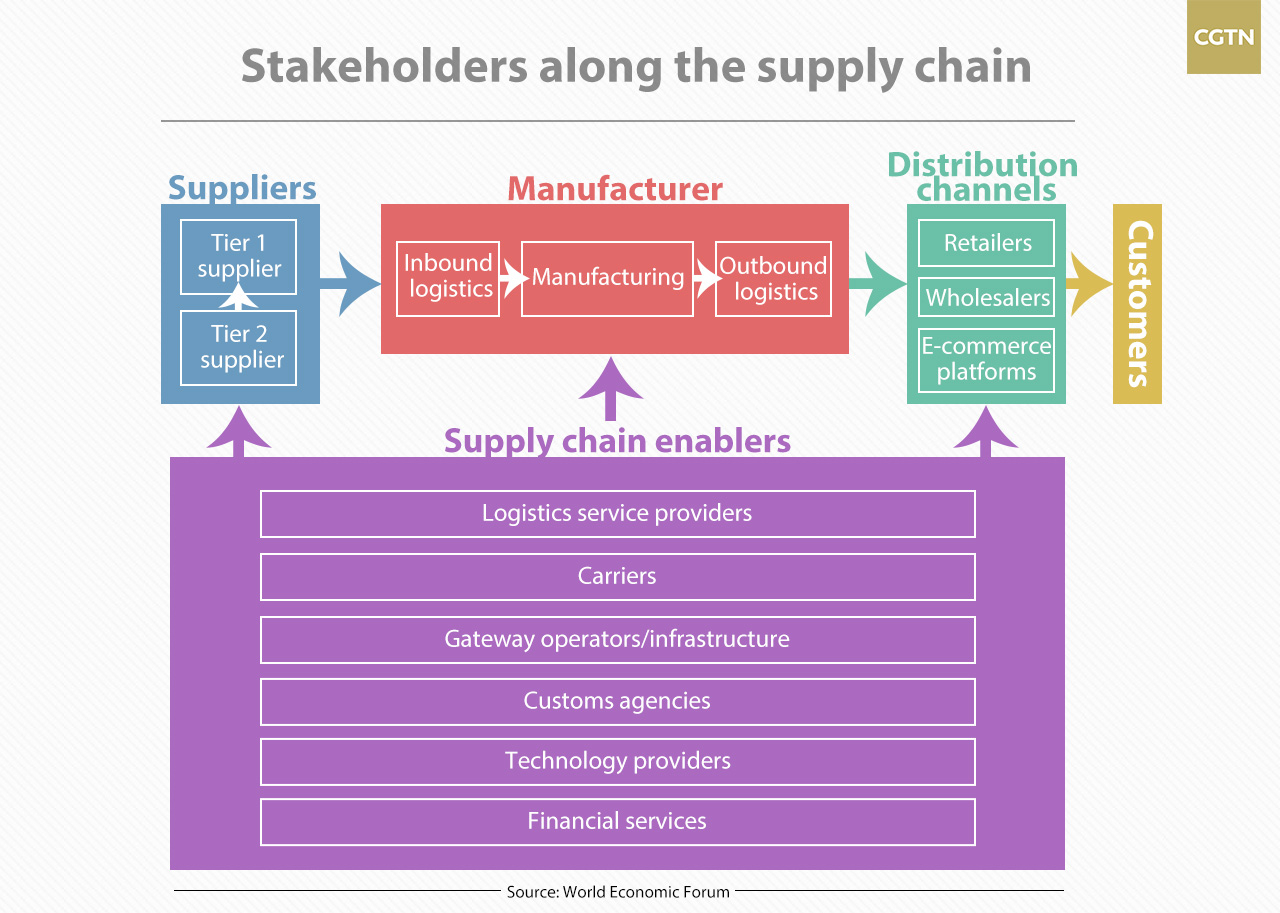

Making innovations in the supply chain not only involves automobile production or trade, but also every link from parts and components to the manufacturing of vehicles, to form a new automotive value chain, according to Cai Jin, vice president of China Federation of Logistics & Purchasing.

He also noted that manufacturing or trade is not the only source of a car's value. The production and sale of parts and components, and the auto aftermarket represent a bulk of the created value. Sixty percent of the profit margin comes from the aftermarket in the auto industry.

Copyright © 2018 CGTN. Beijing ICP prepared NO.16065310-3

Copyright © 2018 CGTN. Beijing ICP prepared NO.16065310-3