41,600 employees laid off.

That is the confirmed layoff number of the U.S. motor vehicles and parts manufacturing in a month between September and October according to current employment statistics.

As one of the major industries in terms of economic scale and employment, the automotive industry in the U.S. has been experiencing a complex situation due to costs rising, sales slowing, emissions curbed, policies changing and the era of electric vehicles which is set to come.

Wide-spread layoffs

In Michigan, as many as 10,800 motor vehicles manufacturing supplier workers have been laid off in one month, with a 26.3 percent decline in total employees, followed by roughly 10,200 workers lost their jobs in motor vehicle parts manufacturing. As the Center for Automotive Research(CAR) revealed, this state holds the highest share at 21.4 percent of U.S. automotive employment at the end of Q1 2019.

But it's not just that.

Almost on the same day as the UAW strike began, roughly 48,000 Michigan state employees were reading a notice that about 30,000 of them would possibly face layoffs in case of a partial shutdown, due to the state officials' disagreement on a government budget, the Detroit News reported.

As America's largest manufacturing sector, automotive industry has been driving the U.S. economy, not to say Michigan.

The state's House Fiscal Agency wrote in an economic outlook that, the level and composition of light motor vehicle sales, as well as the extent to which the domestic nameplates can retain market share, will have a direct impact on Michigan's economy.

However, the U.S. has still pushed China, the world's largest market of new vehicles, away and this may be one of the factors leading to unemployment.

The China-U.S. trade war is just a trigger

From a sense of surface figures, the Chinese market's importance in vehicle sales in the U.S. was not especially significant.

In 2017, only 12 percent of U.S. motor vehicle parts were imported from China according to the U.S. International Trade Administration, but it's second to the biggest U.S. market share owner after Mexico at 25 percentage points.

Does this mean that the China-U.S. trade war had a limited impact on the automotive industry? Definitely no.

First of all, China's vehicle market is large and still fast growing, and the increasing possibility of withdrawing from it will force U.S. automotive giants alter their forecast and strategies. Amidst the obvious global trend of slowing car sales, replacements within automotive market could be more merciless.

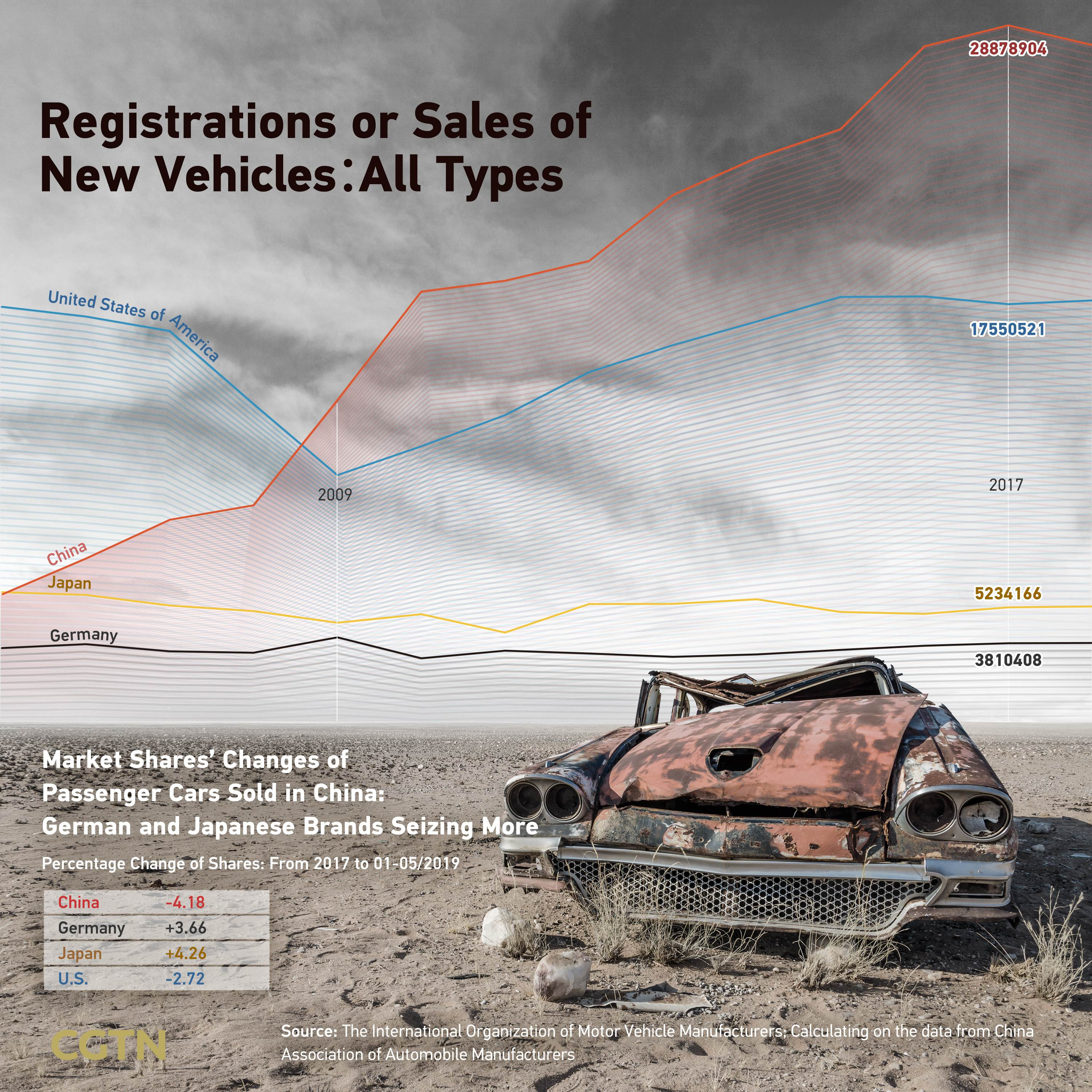

In 2018, China registered or sold almost one third of the world's new vehicles, with a 27.7 percent five-year growth rate compared to that of the U.S. market at only 11.4 percent, according to the International Organization of Motor Vehicle Manufacturers.

After the China-U.S. trade war began, data from the China Association of Automobile Manufacturers observed rapid replacements in China's passenger cars market, driven primarily by German and Japanese companies.

While the share of U.S. vehicles in that market has fallen from 12.30 percent in 2017 to 9.58 percent by May 2019, the market share of Japanese vehicles has grown by 4.26 percentages, rising from 17.01 percent to 21.27 percent. And German vehicles also benefited from a 3.66 percentage-point rise.

In Detroit, Michigan, by September 2019, there was a decrease of domestic export value to China of over a third compared to the same period of 2017. This 1.2-million-U.S.-dollar loss didn't have a major impact in total value, but is a clear sign of a larger market attempting to close its door as a countermeasure.

Additionally, the trade war has raised costs in the U.S.. The CAR estimated the average increase in cost on every U.S.-built vehicle may be 190 U.S. dollars due to tariffs.

Even greater costs touched a raw nerve of big U.S. automotive manufacturers, who have been considering the heavy costs of future plans, particularly those related to electric cars.

Hiring nearly two out of three U.S. autoworkers and involving 250,000 jobs in 2017, the Big-3 auto manufacturers of FCA US, Ford and General Motors have started to believe battery builders are more essential than engine assemblers.

Under the China-U.S. trade war, the car industry shift to electric and autonomous vehicles has become urgent.

Jobs won't return to the U.S.

Ironically, President Trump's policies of bringing back manufacturing jobs may increase a possibility of making the opposite.

U.S. automotive workers are giving way to Mexican workers rather than Chinese workers.

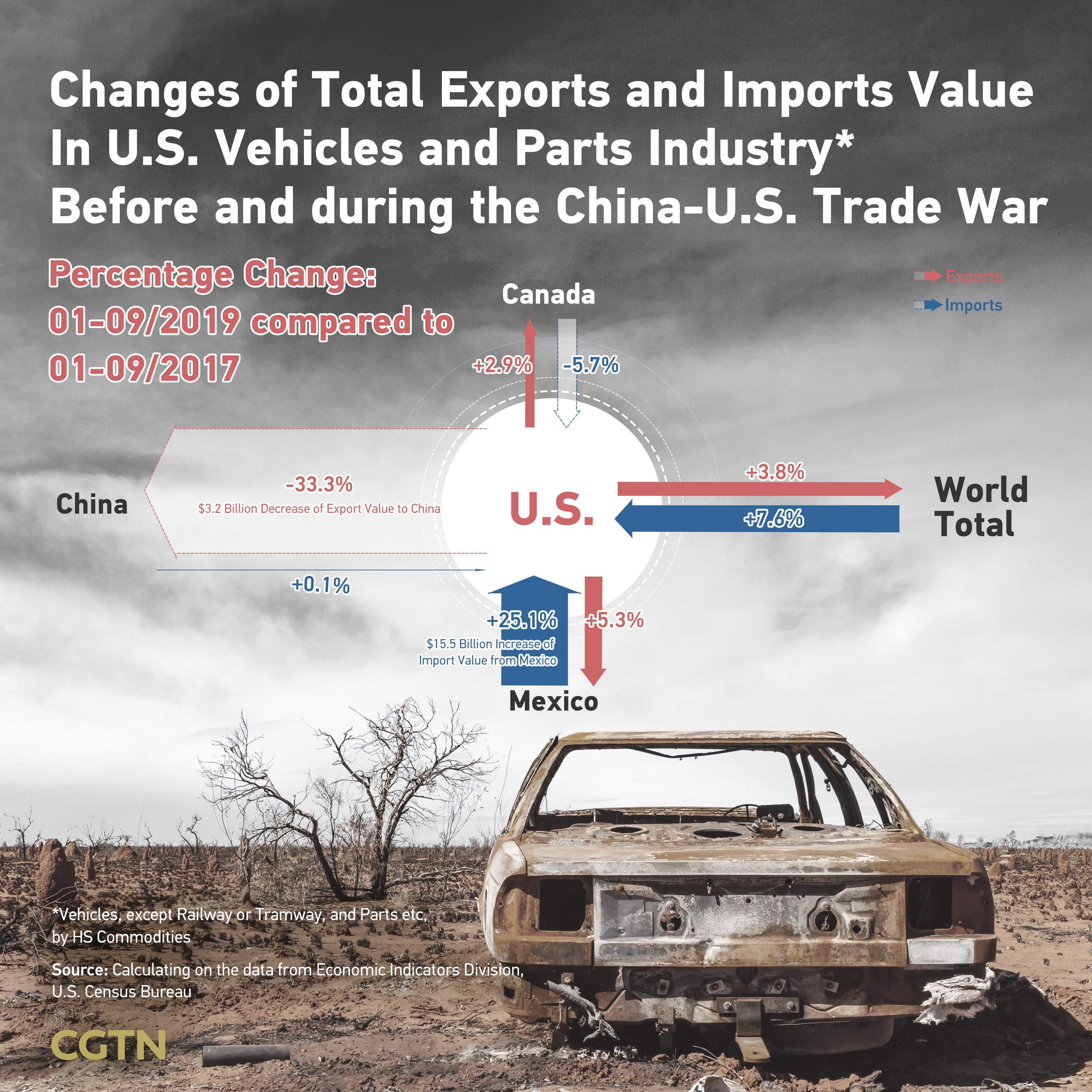

Before and during the China-U.S. trade war, the U.S. export value to China in vehicles and parts industry dropped 33.3 percent in January to September 2019 compared to the same period of 2017, a decrease of as much as 3.2 billion U.S. dollars. Meanwhile, the import value from Mexico to the U.S. during that time substantially increased 15.5 billion U.S. dollars, at a rate of 25.1 percent.

To steady car prices and sales, automotive manufacturers soon turned to an alternative country with lower labor costs instead of moving back to the U.S., owing to the automotive industry's mature cross-border supply chains and the prospect of North American Free Trade Agreement (NAFTA).

At the beginning of 2019, General Motors already took the top position of carmakers in Mexico and has decided to produce the new Chevrolet Blazer SUV in this country, a sign that automakers throughout the NAFTA region are increasingly interconnected.

Also in exports, 55.4 percent of all U.S. total exports were reliant on the Canadian and Mexican vehicle markets in September 2019. However, the whole market size of Canada, America and Mexico in all types of new vehicles in 2018 was just 75 percent of China's market.

Author: Han Mo, Zuo Lin, Liu Jing, Huo Li

Designer: Yu Pianyi

Cover photo designer: Qu Bo

Chief editor: Li Shou'en

Supervisor: Mei Yan