Factories rumbling back into action, workers lining up to get their temperatures checked, trucks carrying loads of heavy metal… these are the signs that manufacturing is back on track in China after the coronavirus shutdown.

For Mu Zhiqiang, owner of a ship coating factory in Lingang Economic and Technological Development Zone in north China's Hebei Province, Monday was the first day operations resumed. With 80 percent of his workforce recruited locally and the rule on mandatory quarantine for returned workers starting to ease, Mu said the restart was smooth for him.

"The restrictions are way less on Monday compared with two weeks ago. Companies can take the initiative to restart operations without prior approval from the governing committee of the development zone," Mu told CGTN.

Barricades intended to bar entry to the development zone were all removed at the weekend. Returned workers are no longer required to go through quarantine if they come from an area with no confirmed cases of coronavirus and if they show no symptoms of coronavirus infection, according to a notice published by the development zone.

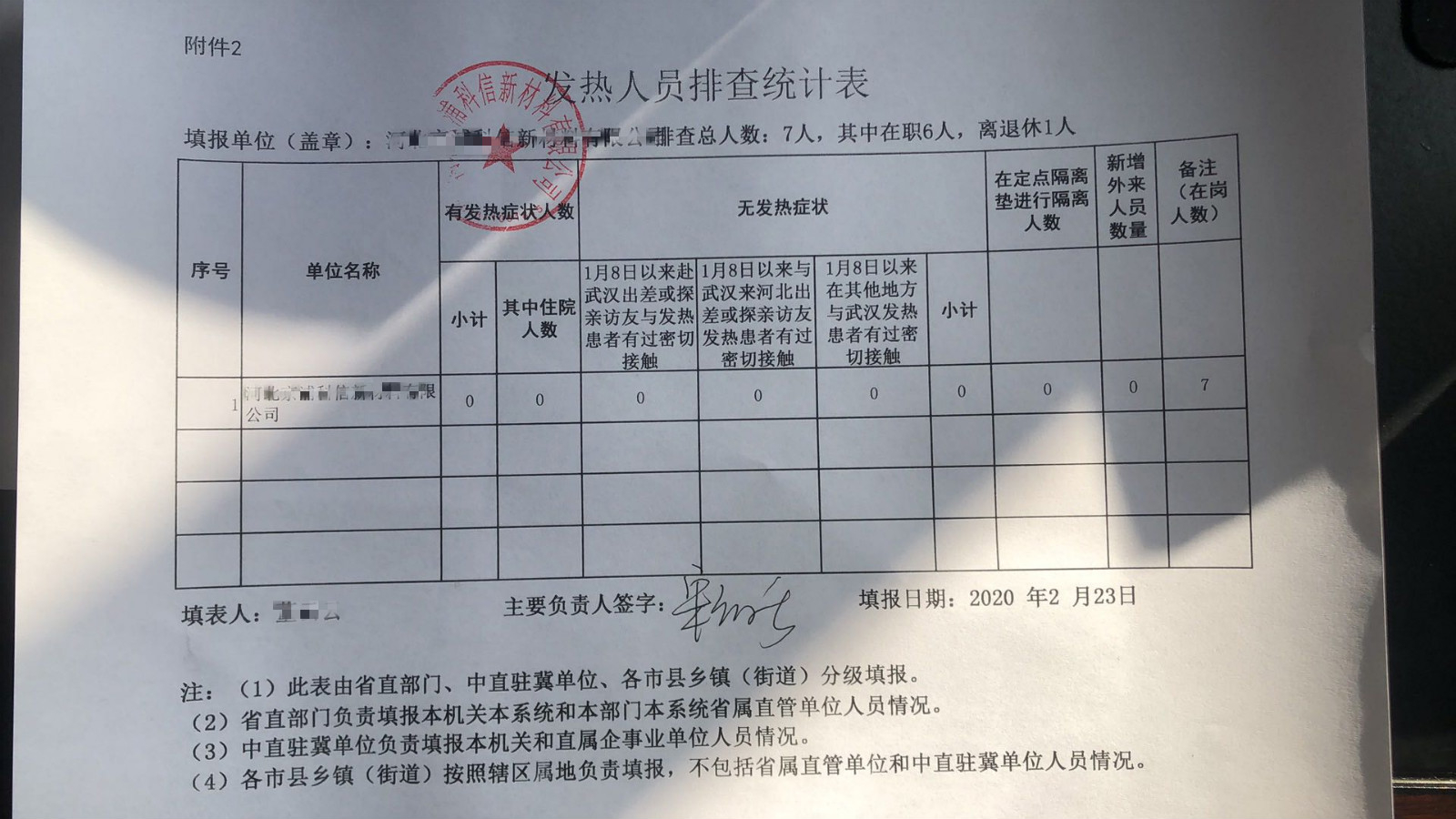

All workers are required to hand in forms to their employers which contain a detailed description of their health conditions and travel history. /Photo courtesy of Mu Zhiqiang

All workers are required to hand in forms to their employers which contain a detailed description of their health conditions and travel history. /Photo courtesy of Mu Zhiqiang

As regions outside the epicenter of Hubei are showing signs of improvement, local and central governments are loosening the restrictions for factories to resume operation. According to the latest figures released by the National Development and Reform Commission, more than 90 percent of large industrial enterprises in Zhejiang Province have restarted, the highest among all provinces, autonomous regions and municipalities.

The restart rate for large industrial enterprises exceeded 70 percent in provinces such as Jiangsu, Shandong, Fujian, Liaoning, Guangdong and Jiangxi. The restart rate for small- and medium-sized companies, on the other hand, is much lower, reaching around 30 percent nationwide, as they found it harder to balance the need to contain the virus while resuming production.

Sun Liangyu, owner of a small furniture factory in Yutian county of Hebei Province, said he did not dare to restart production because his factory cannot meet the standards required for reopening.

Under the local government's rules, returned workers need to be quarantined for 14 days, but at the factory dorm, there is no single room for workers. Moreover, if there are cases of suspected infection, there is no quarantine area to contain the spread of the virus. Bigger companies have the capacity to book hotel rooms, but for a small factory that employs no more than 60 people, the risk is too much.

A worker checks the temperature of a woman at a mask factory in Shanghai, January 31, 2020. /Reuters

A worker checks the temperature of a woman at a mask factory in Shanghai, January 31, 2020. /Reuters

There is no doubt that labor-intensive factories like Sun's are desperate to reopen. Orders are piling up and cash flow is tight. Most of them are in the middle of the supply chain and a suspension in production can result in industry-wide paralysis.

Chen Jianfeng, president of a modular house factory in China's steelmaking hub of Tangshan in Hebei Province, said his factory resumed operation in the middle of the Spring Festival break. Modular houses produced by the factory are used for hospital construction nationwide, but the factory is nonetheless hampered by a suspension in production of downstream materials.

Last week, Apple warned that because its contract manufacturers were ramping up production at a pace more slowly than expected, it anticipated that there would be iPhone supply shortages. It is the first U.S. company to say it would not meet its revenue projections for the current quarter due to the impact of the coronavirus outbreak.

The push to resume production is also seen at the epicenter of the outbreak, in the city of Wuhan, where disruption to the supply chain is most severe. Production lines at Wuhan Dingyi Food Corporation, the company behind the popular instant noodle brand Master Kong, restarted as early as January 28 in order to meet surging demand for instant noodles in coronavirus-hit areas. But while production continues, it is also facing shortages of raw materials.

Customers wear masks as they shop for instant noodles at a supermarket following the coronavirus outbreak in Hong Kong, China, January 30, 2020. /Reuters

Customers wear masks as they shop for instant noodles at a supermarket following the coronavirus outbreak in Hong Kong, China, January 30, 2020. /Reuters

According to a factory manager surnamed Xiao, who prefers not to reveal his first name, oil, seasoning ingredients and flour, some of the basic raw materials for instant noodle production, are running short. The factory may run out of stock by the end of March, but given that instant noodles are critical to food supply, the local government is likely to offer assistance in coordinating the logistics of raw material sourcing, he added.

The factory has been counting on a local workforce, around 100 workers, one fifth of the full-capacity workforce, to sustain production. Now because of labor shortages, seven of the 10 production lines in the factory are idle. The remaining three lines can produce a total of around 40,000 packages of instant noodles every day.

Xiao said the company is planning to call employees in crucial positions back to work, but a detailed plan on how to bring back those workers is still pending. The earliest period in which employees outside Wuhan can return to work is probably around mid-March, he estimated, and before that the factory is likely to continue running below full capacity.

Among the positive signs indicating progress in containing the virus is the easing of travel restrictions. According to the Ministry of Transport, 27 provincial-level regions had resumed inter-provincial and intra-provincial road passenger transport by February 23, while 110 prefecture-level cities and 137 county-level cities had resumed ground public transportation operations.

A man holding a loudspeaker sits on a motorcycle as it travels past a sanitizing vehicle disinfecting the area near residential buildings, Guangdong Province, February 11, 2020. /Reuters

A man holding a loudspeaker sits on a motorcycle as it travels past a sanitizing vehicle disinfecting the area near residential buildings, Guangdong Province, February 11, 2020. /Reuters

But some workers have still been unable to come to work on time due to blocked roads. And some neighborhood communities have barred residents from leaving their apartment complexes, according to Xiao.

At a press conference on Sunday, officials with the Chinese Ministry of Commerce said that obstacles persist which hinder factories from getting production rolling. Among the obstacles cited are lengthy bureaucratic procedures to apply for reopening, a lack of sanitization equipment for workers, labor shortfalls and travel restrictions.

Local commerce departments must realize the importance of resuming business operation, push forward the resumption of production in an orderly manner and minimize the impact of the coronavirus outbreak on production, the officials noted.

(Cover image: Fan Chenxiao)