03:53

Editor's Note: China's congressional system is one of a kind, with deputies to the National People's Congress coming from all walks of life. In this special series, CGTN interviews deputies to find out how they represent the voice of the people and what they bring to the table at China's top legislature during the all-important Two Sessions this year.

Leapfrogging advancements in artificial intelligence technologies have recently brought both enthusiasm and anxiety across workplaces worldwide. It is reviving debate on what is considered a uniquely human job and what can be replaced by machines.

"Regardless of the type of work, with the development of the times and the advancement of technology, the life span of a career cycle is shortening," says Dai Tianfang, a chief technician at Beijing Hangxing Machinery Manufacturing Co., a Chinese firm that makes aerospace equipment.

For the last 34 years, Dai toiled at his company's production plant, and now is the proud holder of the rights to more than ten different inventions, a testament to a true craftsman's spirit: persistence, the pursuit of excellence, and innovation. He considers technology a "force" that can be used to liberate work and productivity.

Flashback to the beginning of his career, Dai recalls first taking up his post in the factory at the age of 19. A lot of manual labor was required then. He and his fellow colleagues eventually developed muscle memories for the precision work through practice – much like how good marksmen can hit a bullseye without even looking.

As the aerospace industry is often at the forefront of high-end manufacturing, it was not long before the idea that brawn trumps the brain at a factory job became an outdated concept.

A technician operates automation equipment at a factory in east China's Zhejiang Province, June 22, 2021. /CFP

A technician operates automation equipment at a factory in east China's Zhejiang Province, June 22, 2021. /CFP

In Dai's role as an on-site operation technician, he was required to set up 3D modeling, integrate flexible manufacturing technology, on top of cutting a work piece. Precision requirements meant room for error in the processed work pieces was within one-fifth of a strand of hair.

Dai is also a lawmaker, as one of the nearly 3,000 deputies to the National People's Congress that convened at the recently-concluded Two Sessions and brought some of the ideas he learned in his years to the country's top legislature.

His proposal is to push for the training of more interdisciplinary talent in China.

Dai explains that an interdisciplinary technician is an on-site engineer. The idea is that this person, when there is any abnormality or problem, would immediately know the theory behind what has gone wrong, and also how to actually fix it on the spot.

He wonders out loud if using "engineer" as a job title will attract more students to pick up a technical major at school, while emphasizing the importance of growing it as a hobby, as the saying goes: "Interest is the best teacher, but interest is not learned in classrooms."

Dai suggests that children should be offered more opportunities to practice hands-on practical skills and help them to build a connection with objects. But Dai recognizes obstacles in his way: these days, when something is broken at home, people tend to buy a new one rather than try to fix it.

Dai himself grew an interest in fixing things as a child and later found the sound of a machine cutting a work piece was like music to his ears. The "exceptionally beautiful" sound means a "perfect" product is about to come out, he tells CGTN in an interview.

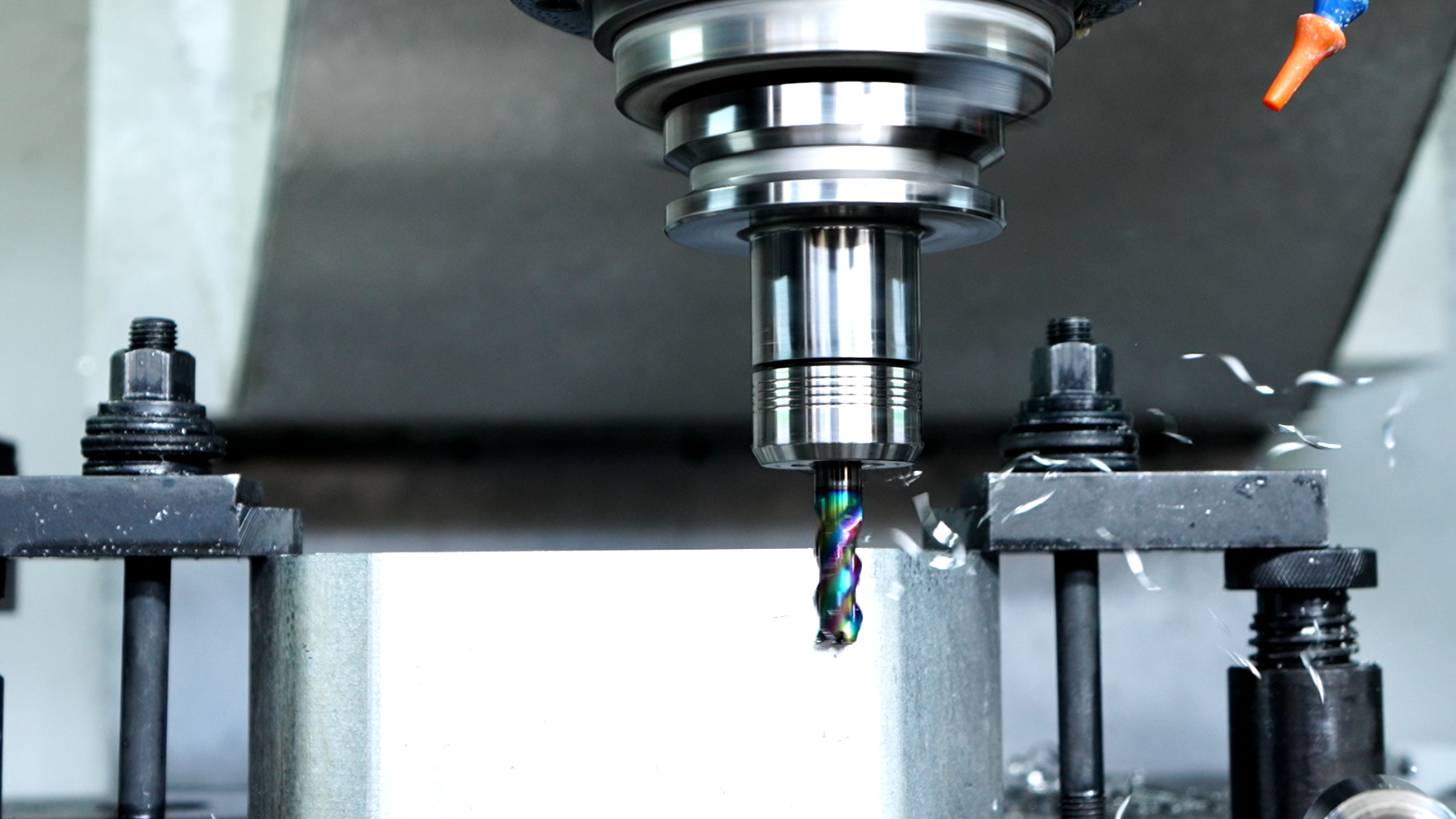

A machine drives a cutter to cut a work piece. /CGTN

A machine drives a cutter to cut a work piece. /CGTN

Apart from a lack of interest in fixing things, there are more reasons that make working in a factory unattractive. Many students would not decide on a career path in high school as they would often pin their hopes on good universities to guarantee them a good office after graduation. The prevalent myth is that going to a vocational college reduces a person's chances for anything more than a repetitive and low-paying job for life, but Dai says this was not true at all.

Dai is a firm believer in the value of non-stop learning at work and giving pay raises in line with skill levels. Referring to breaking the ceiling on occupational skill levels, Dai says that his company has been implementing eight occupational skill levels for years. He says that having more levels of work certifications give technicians more recognition in their professions, offering more goals to hit and providing financial incentives.

First elected a deputy to the National People's Congress in 2018 and starting his second term this year, Dai has always had his focus firmly on improving training and employment for technicians.

A robot arm in a factory plant. /CGTN

A robot arm in a factory plant. /CGTN

During the annual Two Sessions in 2021, he suggested more interactions between companies and vocational colleges. Following this, he was invited to join a national committee for high-end equipment manufacturing as a result of his suggestion. The committee, with representatives from 24 other institutions and 27 colleges, aimed to bridge the gap between what's taught in school and what's adapted in factories.

China amended its Vocational Education Law during the 2022 Two Sessions to offer many favorable clauses toward supporting youngsters to learn skills and attend technical schools. The government's report this year also emphasized "vigorously" developing vocational education.

As China's manufacturing sector advances, the demand for a workforce equipped with good knowledge of technology has increased sharply as well. Intelligent robots, cloud computing, virtual reality and other high-tech technologies and techniques are gradually being applied to the production process.

Dai notes that it may take a while longer for the process for social awareness on the merits of technical jobs to change. But he hopes more people will grow an interest in high-end equipment building industry and choose it as a career in the future.

Reporter: Huo Li

Cameraman: Ma Tianwen

Video editors: Li Yanxing, Huo Li

Copy editor: Teoh El Sen