The Five-hundred-meter Aperture Spherical Radio Telescope (FAST) in Pingtang County, Guizhou Province, southwest China. /CMG

The Five-hundred-meter Aperture Spherical Radio Telescope (FAST) in Pingtang County, Guizhou Province, southwest China. /CMG

China's self-developed intelligent robot systems and platforms have passed the acceptance tests for maintenance service for the country's Five-hundred-meter Aperture Spherical Radio Telescope (FAST), also the world's largest single-dish radio telescope, the China Media Group (CMG) reported on Friday.

Led by the Guizhou Radio Astronomy Observatory, the project is jointly conducted by 10 units, including the National Astronomical Observatories of the Chinese Academy of Sciences and the Harbin Institute of Technology.

Dubbed the 'China Sky Eye,' the telescope is located in a naturally deep and round karst depression in the southwestern province of Guizhou, with a reception area equal to 30 standard football fields.

Sound maintenance is the key task to ensure FAST's observational capability. The robots are able to undertake high-risk operations that cannot be achieved by humans, overcoming climate impact which restricts astronomical operations.

Therefore, they will help safeguard the telescope's operation, increasing its observation duration and efficiency while promoting more scientific results.

"The intelligent robots are expected to add about 30 days to the telescope's observation period annually," said Jiang Peng, FAST's chief engineer.

A view of feed cabin all-weather smart measurement robot of FAST. /CMG

A view of feed cabin all-weather smart measurement robot of FAST. /CMG

Smart robots

These five intelligent robots will be mainly used in testing the supporting cables and pulleys of FAST's feed, the automatic maintenance of its actuators and laser targets on the reflector, the disassembling and installation of feed receivers, the monitoring of radio interference, and the all-weather measurement of its 30-tonne feed cabin.

Among them, the feed cabin all-weather smart measurement robot is a landmark achievement.

Developed by the National Astronomical Observatory, the robot can effectively tackle the technical difficulties of large-scale, high-precision, high-dynamic, and all-weather measurement under field conditions.

The system is a new multi-system data fusion measurement system based on microwave ranging technology, and it is the first application of millimeter-level field measurement technology based on microwave ranging.

It effectively guarantees all-weather high-precision operation of telescopes under the harsh weather conditions in Guizhou Province, providing users with full-time high-precision pointing measurement data which has important practical significance for the expansion of the telescope to higher observation frequency bands.

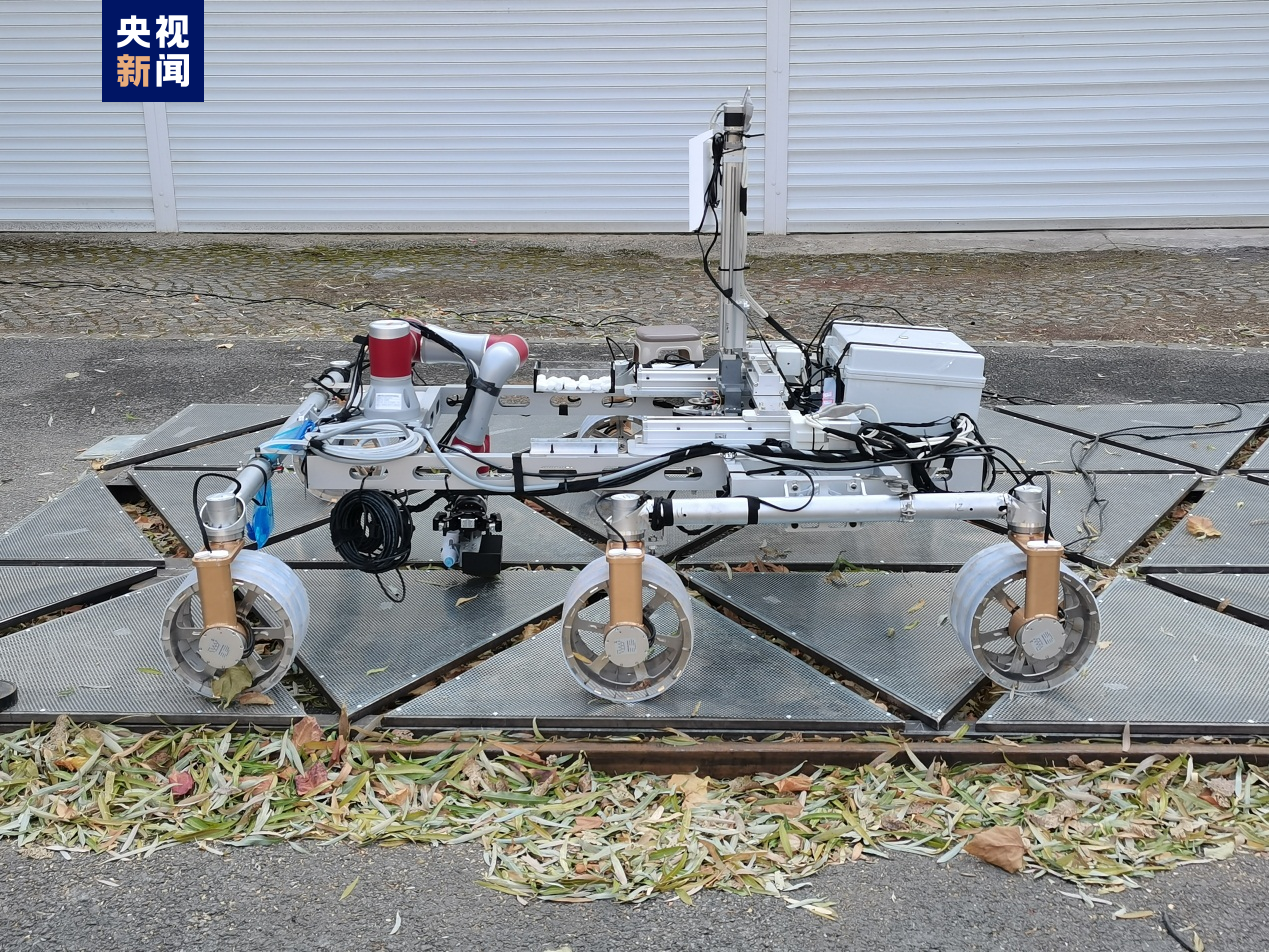

A view of the reflective surface laser target maintenance robot of FAST. /CMG

A view of the reflective surface laser target maintenance robot of FAST. /CMG

In addition, the reflective surface laser target maintenance robot, which can safeguard FAST's actuators and laser targets on the reflector, is another important achievement.

It is jointly developed by the Institute of Automation of the Chinese Academy of Sciences, the National Astronomical Observatory, and Guizhou Radio Astronomy Observatory.

The smart device can efficiently complete tasks of cleaning, disassembly, and replacement of laser targets, successfully realizing automatic maintenance of laser targets on the FAST reflector surface.

The robot has been successfully applied to the replacement and maintenance of FAST reflector laser targets, which will effectively solve the previously existing problems such as high-risk operation risks, low manual maintenance efficiency, and climatic conditions restricting observation, thus greatly improving the efficiency and safety of FAST's maintenance operations.