China

17:17, 15-Nov-2017

Made in China, by robots

By CGTN's Ryan Chua

For decades since China opened up its economy, factories in the country’s prosperous south powered its growth. They produced goods that reached different parts of the world, making China a manufacturing powerhouse on the back of cheap manual labor.

Amid slowing growth, however, the world’s second-largest economy has begun to transition to high-end manufacturing and use robots in workshops that once teemed with workers.

In places like Dongguan, a city that made a name for itself as factory to the world, machines have been replacing humans on the assembly line.

Electronics manufacturer Janus Intelligent Group Corp. Ltd. began automating its factory operations in 2015, encouraged by the local government.

On its production line for smartphone cases, unmanned carts transport metal sheets for cutting and molding by machines, and robotic arms sort the finished pieces.

“Traditionally, workers operated the machines. There was one person for one or two machines,” Zhang Geliang, the company’s production chief, told CGTN’s Assignment Asia.

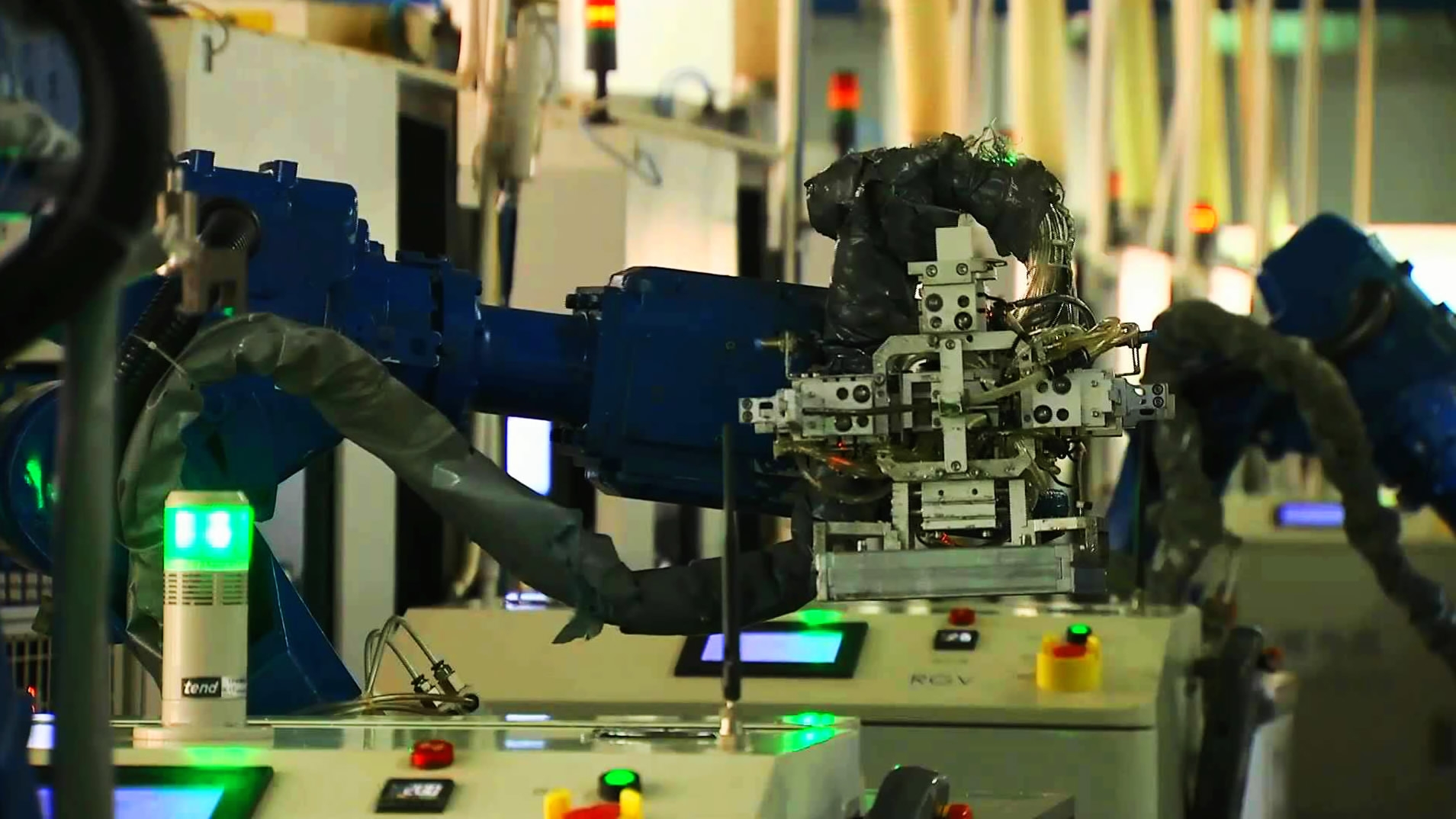

Before using robots, Dongguan's factories relied mostly on manual labor. /CGTN Screenshot

Before using robots, Dongguan's factories relied mostly on manual labor. /CGTN Screenshot

“After we implemented intelligent manufacturing, we reduced our workforce by 80 percent, while daily output rose by 60 percent and product quality improved.”

For many years, Dongguan built its fortunes producing low-end goods like toys and garments for export. But demand for its products plummeted during the 2008 global financial crisis.

Businesses either closed down or moved their production facilities to places with lower wages, as labor costs soared and losses mounted. The city knew its manufacturing sector needed an upgrade.

Reeling from the crisis, Dongguan began to push for high-end manufacturing and the use of industrial robots. In 2014 the city launched a program with an annual budget of 200 million yuan (30 million US dollars) to encourage businesses to automate their assembly lines.

Between September 2014 and January 2017, some 2,600 enterprises received financial support under Dongguan’s robot replacement program, according to the city government.

“In the past three years, machine substitution has led to a rapid growth of investments in industrial innovation. The industrial growth potential of our city is obviously enhanced,” said Zhang Yuqing, chief economist at the city’s economy and information technology bureau.

Aside from reducing the workforce in many companies, automation has changed the nature of the remaining jobs for humans.

Unlike workers from previous generations, Zhang Wen does not perform manual tasks. The 21-year-old from northwest China operates the computers that run machines on the production line of RBD Technology Co. Ltd., a maker of mobile phone parts, including screens.

“In the past, we had to place the glass on the machine manually for polishing, but now the machine hands can do that. So workers can move to new positions and learn new skills,” he said.

RBD Technology’s officials said the company’s production capacity rose five times since it started using robots in 2016. And it’s just the beginning, said Bao Zhongwen, the company’s human resources manager.

“There will be no one in the workshops, and the only people inside will be the ones who perform maintenance tasks,” he said.

Automation is also yielding higher profits for companies, despite the high cost of acquiring robots.

“We recover the cost of robots in just one year. The initial investment is huge, but the company can get better benefits from it, as production costs are decreasing sharply,” said Liu Chanjun, factory director of Marco Polo Group, a ceramics manufacturer.

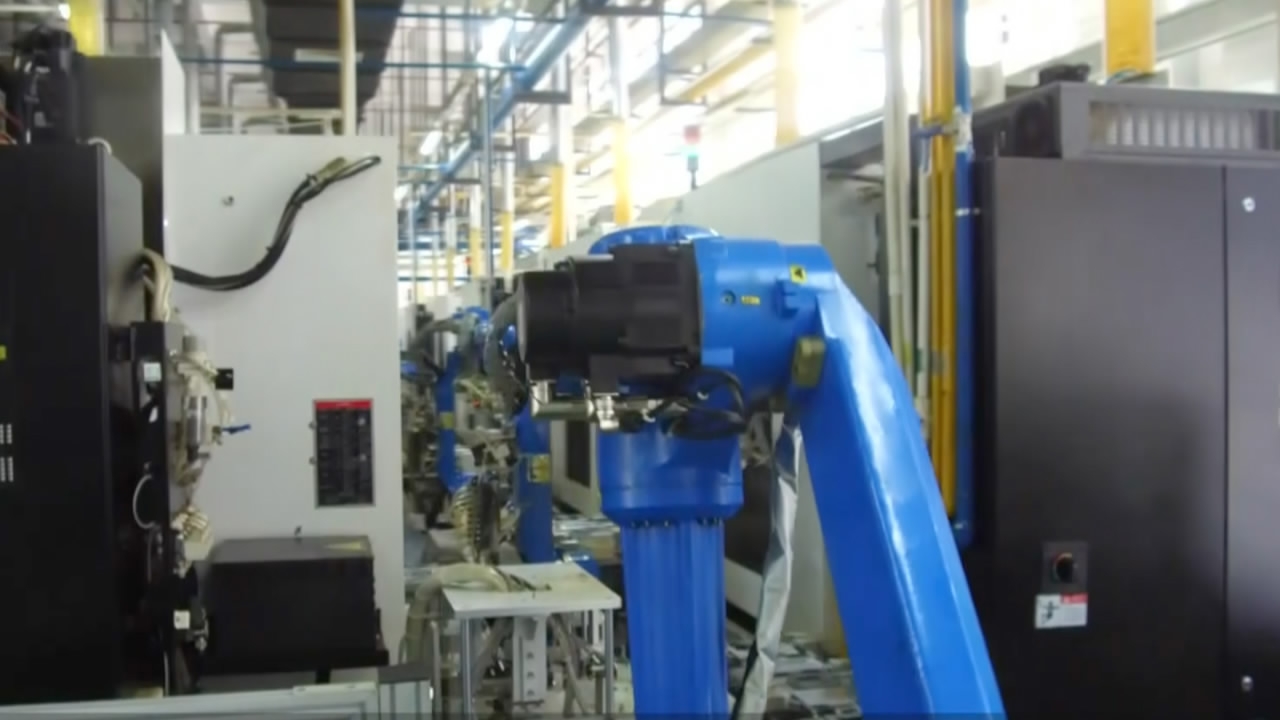

A machine processes sheets of glass for molding into phone screens in this factory for mobile phone parts. /CGTN Screenshot

A machine processes sheets of glass for molding into phone screens in this factory for mobile phone parts. /CGTN Screenshot

Dongguan’s government wants the city to be a trailblazer in the use of industrial robots in China. It is playing an active part in the so-called “Made in China 2025” plan, a blueprint for upgrading Chinese industry using advanced technology.

“We are greatly stimulating the power of our enterprises through transformation and upgrading,” said the economist Zhang.

China is the world’s largest market for industrial robots followed by South Korea, Japan, the US and Germany, according to the International Federation of Robotics. China accounted for 30 percent of the total supply of industrial robots in 2016.

By 2020, the country aims to manufacture at least 100,000 robots for industrial use domestically. For workshops in cities like Dongguan, that means more and more machines taking charge.

Assignment Asia is a 30-minute current affairs program that takes an in-depth look at stories from all over Asia. It airs Saturday at 9.30 p.m. BJT (1330GMT) on CGTN, with rebroadcasts Sunday 5.30 a.m. (2130GMT) and 2.30 p.m. (0630GMT), Monday 9.30 a.m. (0130GMT) and Tuesday 1.30 p.m. (0530GMT).

1893km

SITEMAP

Copyright © 2018 CGTN. Beijing ICP prepared NO.16065310-3

Copyright © 2018 CGTN. Beijing ICP prepared NO.16065310-3