15:22, 18-Sep-2018

Innovation in 4th Industrial Revolution: Wuxi factory embraces new technologies for smarter production

Updated

14:47, 21-Sep-2018

03:18

Just before the various economic leaders taking part in this week's conference descended on Tianjin, the World Economic Forum released its list of the nine most advanced factories on the planet, which are putting the cutting-edge ideas and technologies of the Fourth Industrial Revolution into action. CGTN's Xu Mengqi visited one of these state-of-the-art production hubs in East China's Wuxi, and brought us this report.

You're looking at a smart factory - the starting point for much of the technology driving the fourth industrial revolution.

This factory, which makes diesel engine parts, is a German-Chinese joint venture geared towards making high efficiency and low emission products.

And it's making them with the help of industry 4.0 technologies.

WANG WEILIANG, REGIONAL PRESIDENT BOSCH POWERTRAIN SOLUTIONS CHINA "Bosch was one of the initiators of connected manufacturing and Industry 4.0 when the field was defined in 2013. Since then Bosch has developed itself as a leading provider and leading user of Industry 4.0 technologies and concepts."

STUART BROWN, TECHNICAL FUNCTIONS DIRECTOR BOSCH AUTOMOTIVE DIESEL SYSTEMS "What we mean by industry 4.0 is we can connect our systems. It's about connectivity. So we create an industrial IoT framework and in this way we can gather more data about our systems. That allows us to identify hidden root causes and forecast future actions."

It is literally data about everything, from raw materials, to tools and machines that are being used.

Reporter: "So I gather from the monitoring screen that green indicates the machines are running just fine, and red probably indicates a problem. How do you know that?"

SHEN TANGFU, SENIOR ENGINEER BOSCH AUTOMOTIVE DIESEL SYSTEMS "Because we installed sensors in each machine, and we also applied software solutions to collect all the data. So when there's a problem in the machine, the system will indicate the problem in the system alarm list and we can go deeper into the system to see where the deviation is coming from."

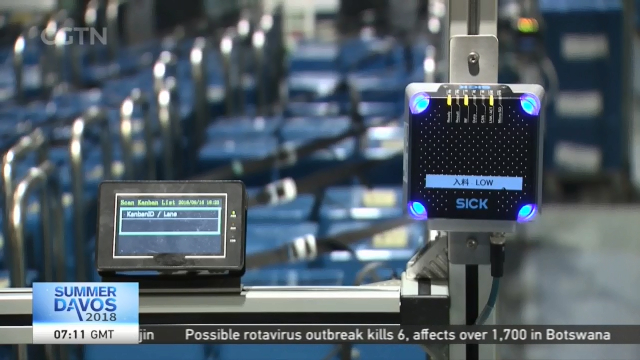

XU MENGQI WUXI, JIANGSU "This is where raw materials and semi-finished goods are temporarily held before moving on to the next stage. Readable tags are attached to the boxes so that the stock management system can automatically allocate lanes for incoming items, while also logging stock levels in real-time."

The process is more efficient, and it also lessens the risk of human error.

But high levels of automation and connectivity also means the factory needs bright minds that know how to craft them.

WANG WEILIANG, REGIONAL PRESIDENT BOSCH POWERTRAIN SOLUTIONS CHINA "With this in sight, innovative solutions can be developed to improve performance in ways that are much faster, more targeted and more automated to create much more flexibility to our productivity."

So above the physical and already highly-automated production lines, a web of connected devices that exists only in the form of data. And right there in the data, lies the future of manufacturing. XMQ, CGTN, Wuxi, Jiangsu province.

SITEMAP

Copyright © 2018 CGTN. Beijing ICP prepared NO.16065310-3

Copyright © 2018 CGTN. Beijing ICP prepared NO.16065310-3