Business

12:55, 06-Sep-2017

The Big Picture: Lighting up

By CGTN's Han Bin, Huang Xiaodong

China aims to raise its position in the global industrial chain: from a big manufacturing hub to a great manufacturing powerhouse.

The biggest question is: how to make domestic suppliers more competitive in the global market?

In the big picture of China, the manufacturing industry is under huge pressure. CGTN reporters visited OPPLE, one of China’s leading lighting companies, to see the impact of economic slowdown and hear the firm’s answers to the big challenges.

OPPLE Lighting Chairman Wang Yaohai emphasized the importance of one key ingredient -- quality.

"China’s manufacturing sectors, at the low end, are facing similar problems of overcapacity," Wang told CGTN. "On the contrary, consumption is upgrading, and the demand for better and targeted products in the EU and US markets has been on the rise. The Chinese enterprises are very competitive in overseas markets, the key is quality.”

OPPLE Lighting Chairman Wang Yaohai, who founded the company in 1996. /CGTN Photo

OPPLE Lighting Chairman Wang Yaohai, who founded the company in 1996. /CGTN Photo

Lighting up manufacturing

Wang says that lighting has a great advantage. It is the most basic necessity of life. As long as there’s night, there’s always a need for illumination, so the market demand will always be there.

“The technical level, the threshold for entry is relatively low, but the threshold is high if you want to do it well. Because traditional lighting in the past relied on big foreign brands, like GE, Phillips, Osram… Today, new technology has pulled the entire industry’s domestic and overseas technology to the same level,” Wang added.

OPPLE Lighting production lines in Zhongshan, Guangdong Province, and Wujiang, Jiangsu Province. /CGTN Photo

OPPLE Lighting production lines in Zhongshan, Guangdong Province, and Wujiang, Jiangsu Province. /CGTN Photo

Zhou Xiaoying has worked for OPPLE Lighting since the company was established in 1996. She used to repeat the same action over 10,000 times each day on the production line. She says the biggest change in the lighting industry over the years has been the evolution of products.

Incandescent bulbs were replaced by energy saving bulbs, then the energy saving bulbs were replaced by LED bulbs. “A worker will be let go, if he or she doesn’t change,” she added.

Zhou Xiaoying, worker at OPPLE Lighting. /CGTN Photo

Zhou Xiaoying, worker at OPPLE Lighting. /CGTN Photo

Technological improvements are also changing the workforce. Gone are the days when a company could thrive by offering low-price products. And the number of workers on the production lines will gradually decline due to the introduction of robots.

Zhou says she has a deep affection for the industry, but her children would definitely choose a different job. The decline of the manufacturing industry means it is no longer a top career choice for the younger generation.

Zhou Xiaoying and her husband Zhou Shuiping rent a small house near the factory. He has seen the hard times of China’s manufacturing slowdown and changed jobs many times before joining OPPLE Lighting five years ago. /CGTN Photo

Zhou Xiaoying and her husband Zhou Shuiping rent a small house near the factory. He has seen the hard times of China’s manufacturing slowdown and changed jobs many times before joining OPPLE Lighting five years ago. /CGTN Photo

Made in China 2025

China has been the world’s factory for quite some time and consumers are familiar with the term Made in China, which is often associated with low cost and poor quality products. But things are changing. The country's manufacturing sectors are trying hard to seek innovation in high-end products, and this is where Made in China 2025 comes in.

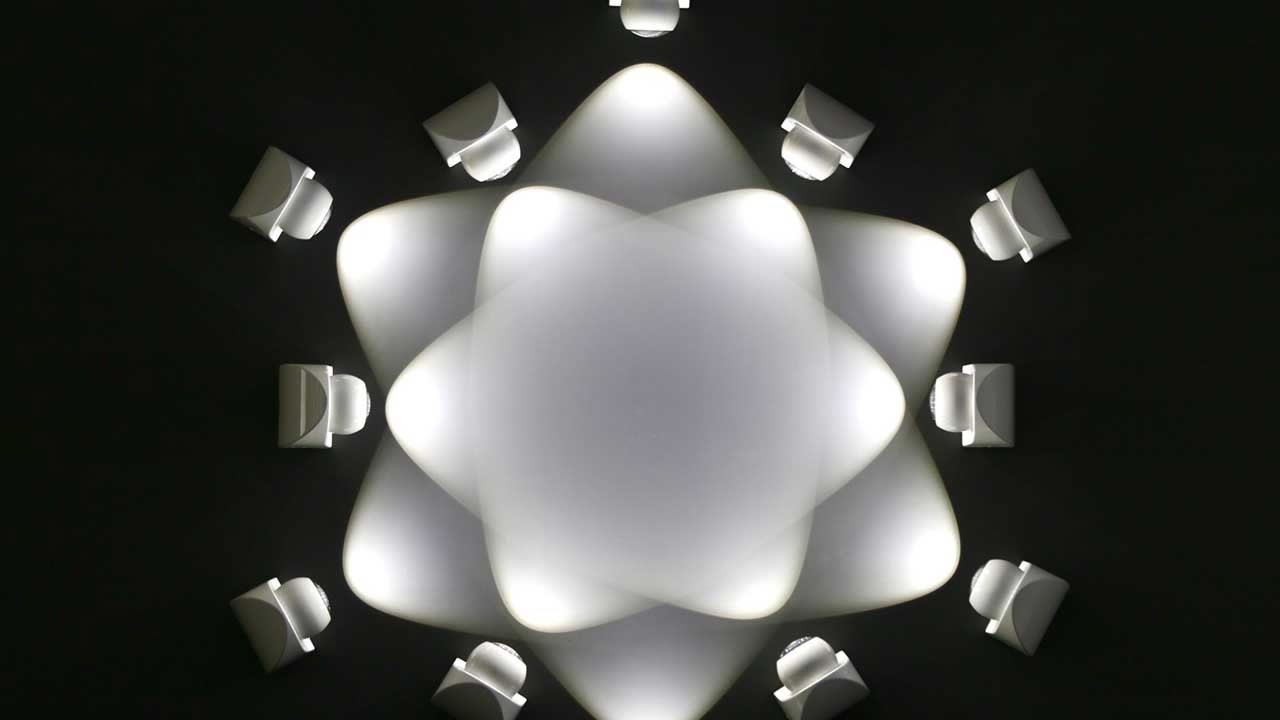

OPPLE Lighting product. /CGTN Photo

OPPLE Lighting product. /CGTN Photo

China aims to build a smarter, greener and more service-oriented manufacturing sector, to transform the country from a manufacturing axis into a manufacturing power.

OPPLE Lighting’s expansion reflects that trend. China’s technological innovation still has a long way to go, but it is already lighting up the global manufacturing industry.

1072km

SITEMAP

Copyright © 2018 CGTN. Beijing ICP prepared NO.16065310-3

Copyright © 2018 CGTN. Beijing ICP prepared NO.16065310-3