Business

18:12, 24-Jul-2018

BRICS Rising Star: BioArchitects' 3D printing technology

Updated

17:24, 27-Jul-2018

By CGTN’s Paulo Cabral

02:37

3D printing is making a big difference in the healthcare of BRICS nation Brazil. Local company BioArchitects uses metal 3D printing technology to create patient-specific, biocompatible implants that replace hard tissue.

The company was founded by a young entrepreneur called Felipe Marques, who saw potential in investing in medical 3D printing four years ago.

"The fourth Industrial Revolution arises from the combination of many different technologies, and I believe 3D printing is one of them,” Marques said. “It will change everything, from how you perform surgery, which is our case here, to any other product you [can] purchase."

From computer modeling based on CAT scan imagery, BioArchitects can print exact 3D models of a patients' organ. Allowing doctors to actually be able to see and manipulate a replica of what they will find when they operate. Surgeons can even choose the exact location of an incision before getting to the operation room.

“Having the possibility of observing all anatomical structures, and of actually practicing the surgery beforehand, enormously increases patients' safety,” said heart surgeon Moise Dalva.

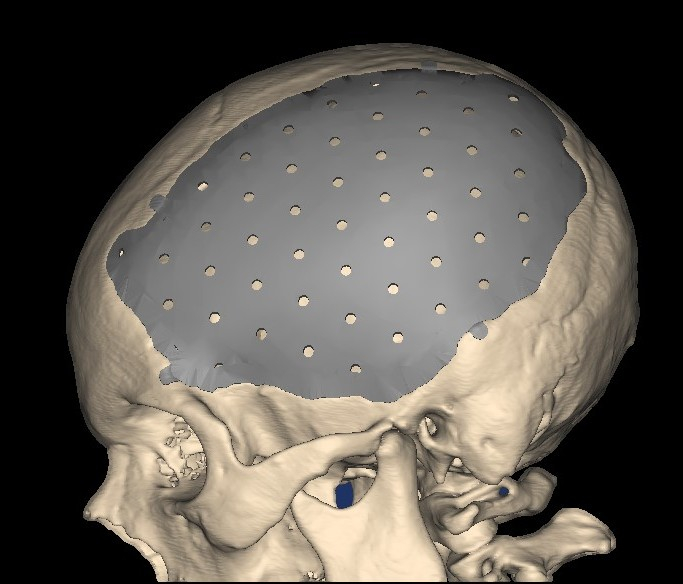

A 3D printed craniofacial implant. / VCG Photo

A 3D printed craniofacial implant. / VCG Photo

Besides, 3D printing can also be used for educational purposes, such as medical training and simulated operations.

BioArchitects also make prosthetics with the technology. Their titanium plate was the first of its kind to be approved for use by the US Food and Drug Administration (FDA).

Marques believes 3D printing has huge potential for developing a customized product market.

"I am sure that as the technology develops and 3D printing becomes cheaper and quicker, this will become mass market," said Marques.

SITEMAP

Copyright © 2018 CGTN. Beijing ICP prepared NO.16065310-3

Copyright © 2018 CGTN. Beijing ICP prepared NO.16065310-3