Tech & Sci

14:11, 13-Jan-2019

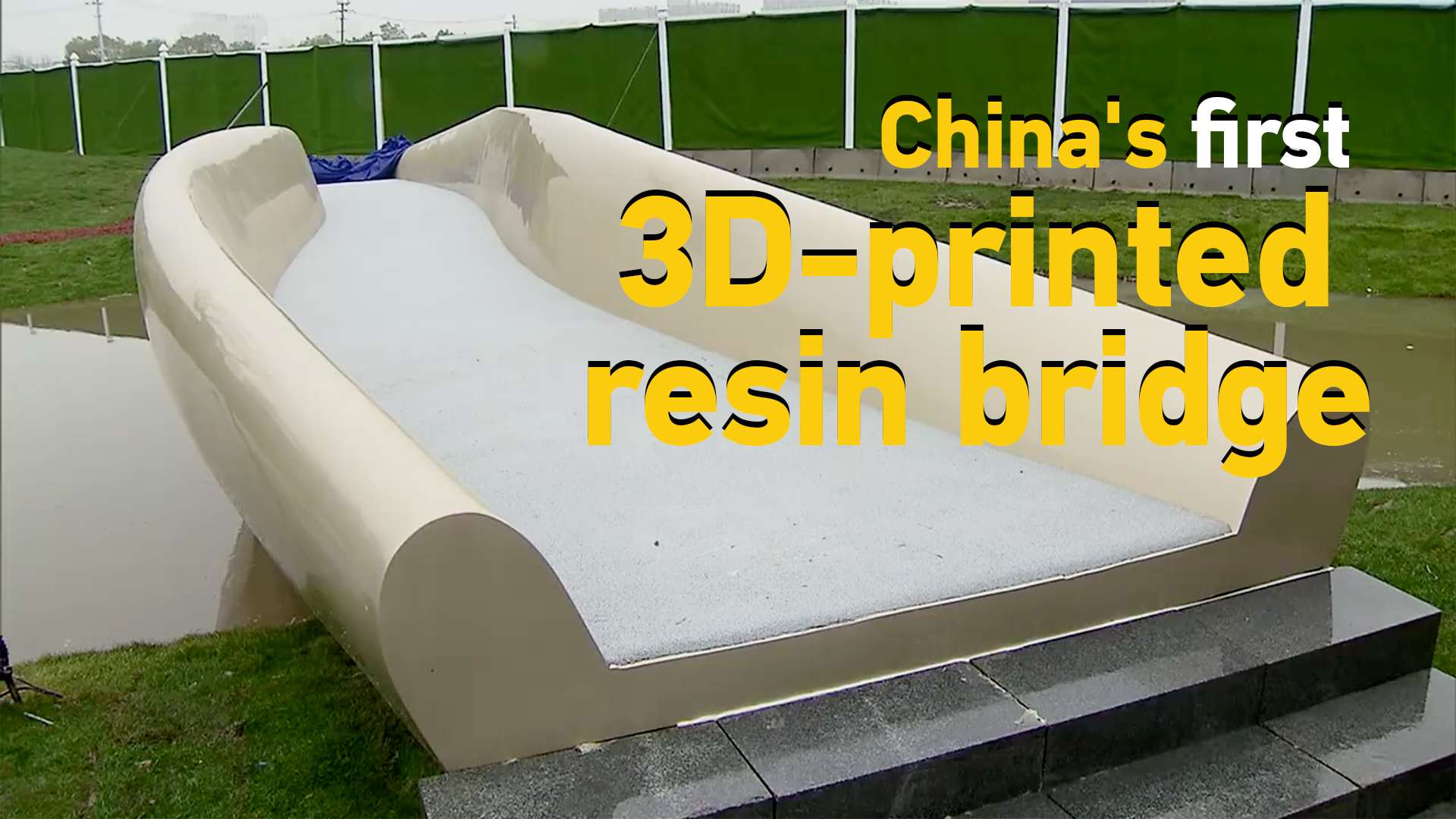

China's first 3D-printed bridge ready to welcome visitors

Updated

13:37, 16-Jan-2019

CGTN

00:52

China's first 3D-printed bridge set up in Shanghai's Putuo District on Friday. At the unveiling ceremony, the landscape bridge, which is 15.25 meters in length, 3.8 meters in width and 1.2 meters in height, was decorated with a coat of fresh paint.

It took designers over six months to chart the bridge, but only 35 days to mold the S-shaped metal-gilded bridge at one stretch by means of 3D printing technology, according to Chen Xiaoming, general engineer of the manufacturer Shanghai Construction Group (SCG).

China's first 3D-printed bridge, Shanghai /VCG Photo

China's first 3D-printed bridge, Shanghai /VCG Photo

Compared to traditional bridges, the high-tech bridge was made from resin and fiberglass instead of concrete and steel, which holds even greater weight capacity, and is safe for pedestrians.

During the construction, two robotic arms were applied to create all the main parts, helping save costs and improving efficiency. People responsible for the project said the bridge can be used for 30 years.

3D-printing technology in the construction industry

The 3D printer which is responsible for creating the bridge girder. /VCG Photo

The 3D printer which is responsible for creating the bridge girder. /VCG Photo

3D-printing technology is nothing new, it has been widely applied to print everything you can imagine, from little gadgets to body parts, from household items to public infrastructure.

Due to a gradual decline in human labor, China's building industry, where has a huge demand for a labor force, had to rethink their transformation.

According to an industry expert, 3D-printing technology will save construction companies up to 50 percent on the human cost of a building a house, offsetting the shortage of workers.

What's more, seeking a greener development path is also what the country has always advocated.

With the advent of 3D-printing, new material can now take the place of lumber in construction. This is a great advancement for the ecological development and can be a lifesaver for China's lumber industry.

(With input from Reuters)

SITEMAP

Copyright © 2018 CGTN. Beijing ICP prepared NO.16065310-3

Copyright © 2018 CGTN. Beijing ICP prepared NO.16065310-3