Analysis: C919 is a challenger to global commercial aviation market

2017-05-05 15:32 GMT+8

1090km to Beijing

Editor

Zhang Yu

Guest commentary by Li Xinyuan

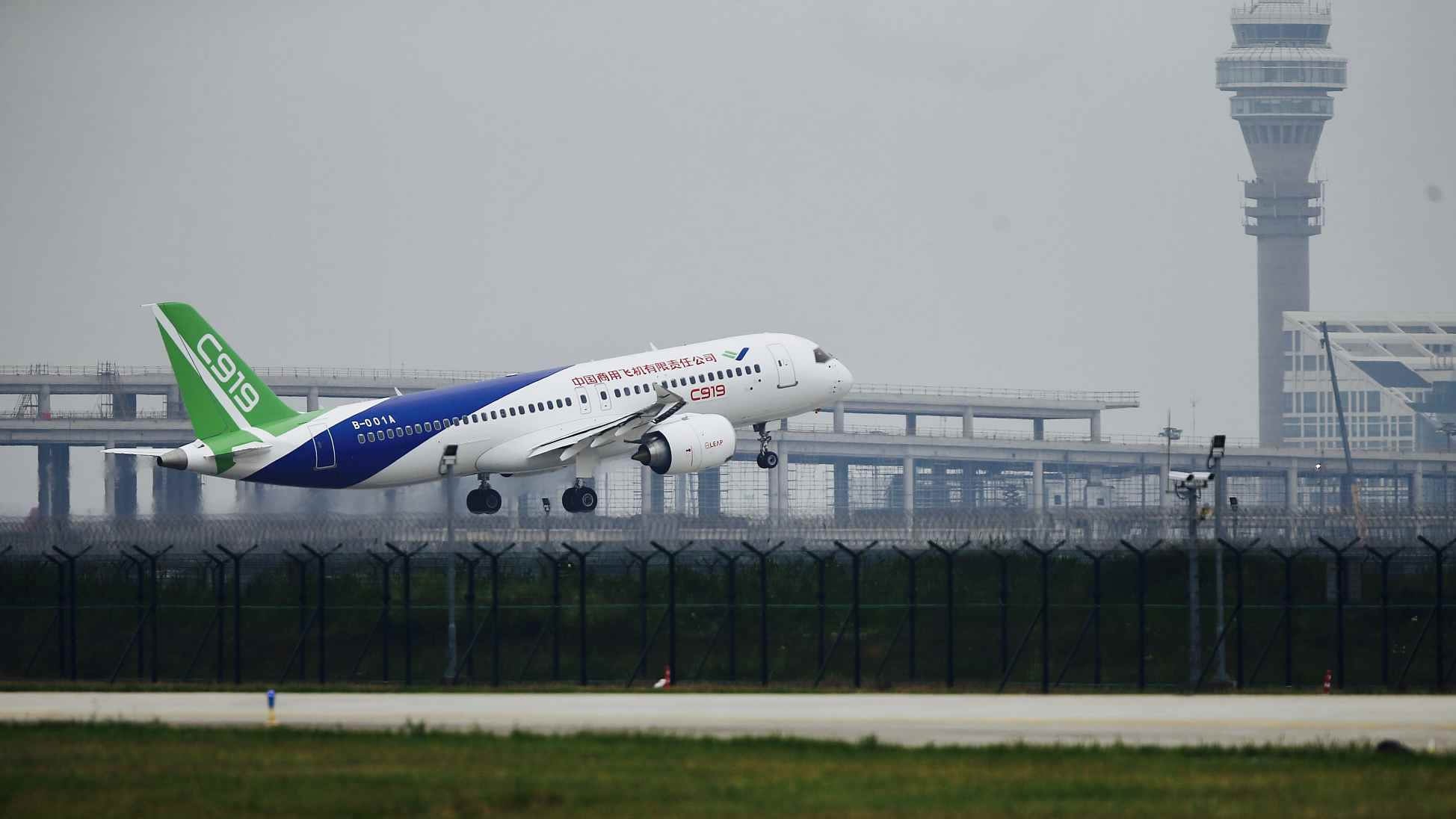

The successful maiden flight by C919, China's first homegrown large passenger aircraft, marks a milestone in the country's aviation history: it means design and integrated manufacturing of large passenger aircraft has reached the international advanced level.

Made by the Commercial Aircraft Corp. of China (COMAC), the twin-engine and single-aisle C919 has three capacity layouts -- with either 156, 169 or 175 seats. Its standard cruising range is 4,075 kilometers, with a maximum of 5,555 kilometers without refueling. Its performance indicators are similar to the Boeing 737MAX and Airbus A320NEO. No wonder it is widely considered as a potential rival to the two best-selling narrow-body planes.

Cabin of C919. /CFP Photo

The development of C919 is of great significance for the country's aviation industry. Compared to eye-catching homegrown military aircraft in recent decades, the absence of operational homegrown large passenger aircraft is almost embarrassing.

According to Aviation Weekly, the output value of the world's passenger aircraft between 2015 and 2019 is estimated to be 16 times higher than that of fighter aircraft. Moreover, the former has better performance in boosting related industries. Passenger aircraft have stricter requirement in terms of safety, efficiency and eco-economy than their military counterparts. Therefore, passenger aircraft manufacturers not only need to show better design technique and management capability, but also a complete industrial chain for support. These barriers led to long-time dominance by Boeing and Airbus in the global commercial aviation market.

Initiated in 2006, the C919 was one of the 16 key projects in China's medium- and long-term science and technology planning. Hence, to research and develop a domestically-built large passenger aircraft is a starting point and national strategy for innovation.

More importantly, the C919 project pushes forward the national aviation technology and management to a higher level. It passed 118 technical tests and made breakthroughs including aerodynamic shape optimization and supercritical airfoil design. Compared to its potential rivals, the C919 has noise reduction of 10 decibels, halved pollution emissions, and its fuel consumption would be reduced by 12 to 15 percent. The aircraft's design and development involved more than 200 aircraft component manufacturers and research teams from 36 institutions nationwide. Over 200,000 technicians participated in its production cycle. The joint collaboration provides a platform for aviation talents, especially the younger generation to grow up and stand out.

Cockpit of C919. /CFP Photo

Challenges ahead

After its maiden flight, the C919 faces plenty of technology verifications and airworthiness validation before production and delivery. It will definitely become a challenger to the Airbus and Boeing duopoly by then.

Boeing predicts that single-aisle aircraft delivery will hit 26,730, worth 2.58 trillion US dollars, by 2034. China will need 5,110 single-aisle aircraft, accounting for 75 percent of its total purchase volume. Therefore, the single-aisle passenger aircraft market is a vast battlefield which leaves huge space for the C919 to explore. China will be its preliminary target as the country is the largest growing market in commercial aviation.

As a latecomer, however, COMAC has yet to compete with its counterparts like Boeing and Airbus, and an appropriate development strategy is a must for future competition. So far, COMAC has received orders for 570 of the planes from 23 clients from home and abroad, which is higher than its expectation. Whether it can set foot in the domestic market and challenge its foreign counterparts rests on two factors. On one hand, COMAC should deliver C919 aircraft on time and establish a good reputation based on excellent flight experiences. On the other hand, China should enhance research and development levels in airborne equipment and aero engines, cut the cost by looking for alternative solutions to its high value-added ancillary equipment, so as to pave the way for a more flexible market-oriented strategy.

(Dr. Li Xinyuan is a senior engineer from the Flight Physics Research Center at China Aeronautical Establishment. The article reflects the author's opinion, not necessarily the view of CGTN.)

1090km

Copyright © 2017