Technology

11:26, 27-Nov-2017

Chinese company seeking titanium to reach the bottom of the sea

By Gong Zhe

A Chinese state-owned company is building a titanium sphere that can carry humans to the deepest ocean, which is about 10,000 meters below sea level.

The company, Baoji Titanium Industry headquartered in northwestern China's Shaanxi Province, has set 2020 as the year to help Chinese people see the "true bottom of the sea" with naked eyes.

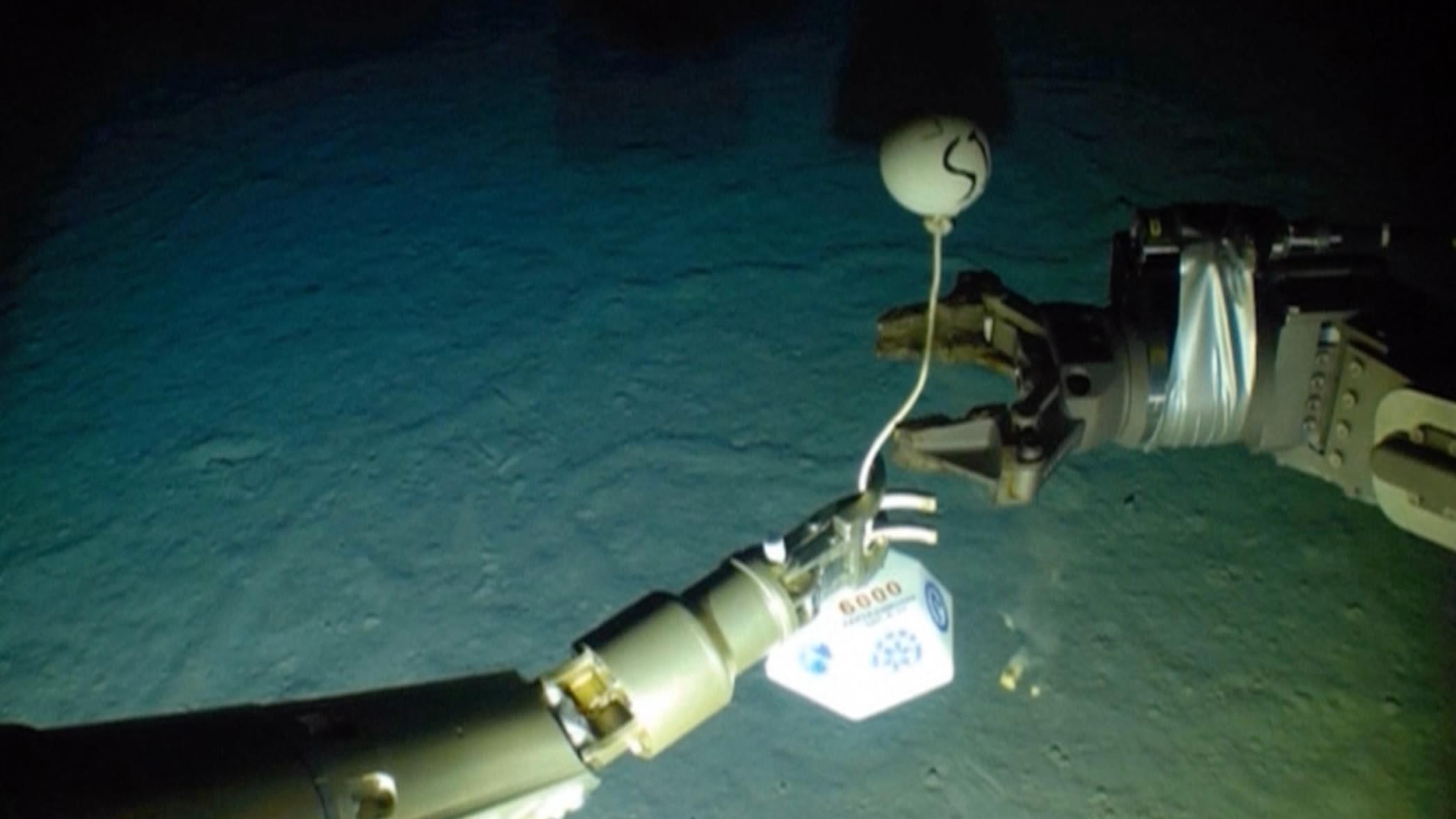

The titanium sphere build by Baotai /Screenshot from CCTV

The titanium sphere build by Baotai /Screenshot from CCTV

Why titanium?

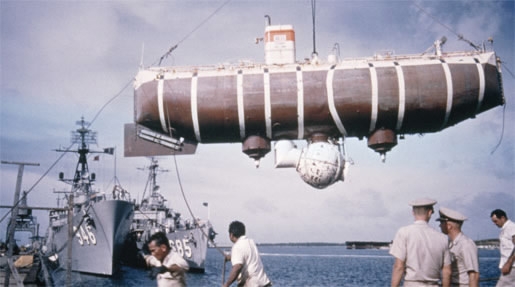

The first time human reached the sea bottom dated back to 1960, when Trieste, a Swiss-designed, Italian-built "bathyscaphe" carried two people to the Challenger Deep near Guam in the Pacific. The measured depth was 10,911 meters, just three meters deeper than James Cameron's diving.

The bathyscaphe Trieste /US National Ocean Service Photo

The bathyscaphe Trieste /US National Ocean Service Photo

The sphere used to carry people on the Trieste was made of steel.

Canadian film director James Cameron, creator of Aliens, Terminator 2: Judgment Day, Titanic and the 2007 movie sensation Avatar, reached 10,908 meters with a steel submersible to shoot his 2014 documentary Deepsea Challenge 3D.

Cameron in a submersible that dived more than 10,000 meters deep in the Mariana Trench. /Screenshot from National Geographic

Cameron in a submersible that dived more than 10,000 meters deep in the Mariana Trench. /Screenshot from National Geographic

So why would the Chinese use titanium instead of steel? Deputy general manager of the company Wang Dingchun gave two reasons:

"The submersible will be used for 30 years. So it has to be corrosion resistant. Our company can make titanium alloy that's almost corrosion-free," Wang told CCTV.

"The elasticity of the metal is also important," he added. "It offers much better protection against the massive pressure deep in the sea [than steel]."

Wang talks about the titanium sphere. /Screenshot from CCTV

Wang talks about the titanium sphere. /Screenshot from CCTV

Get the hard job done

China has many experienced companies that can process steel. But it's not the case for titanium.

"There's very little appliance of this metal in China," said Jia Shuaixiao, general manager of the company.

The engineers chose the hard way to build the sphere in order to make it more reliable.

"The traditional method of building a metal sphere is to first build the slices and then weld them together, resulting in many seams," Wang explained. "But we directly made two hemispheres, and weld only once. Thus the sphere will be more solid."

Engineers at Baotai polishing a titanium hemisphere /Screenshot from CCTV

Engineers at Baotai polishing a titanium hemisphere /Screenshot from CCTV

If the sphere survives the 2020 deep-sea exploration, it may give huge confidence to titanium processors across the country.

SITEMAP

Copyright © 2018 CGTN. Beijing ICP prepared NO.16065310-3

Copyright © 2018 CGTN. Beijing ICP prepared NO.16065310-3