Tech & Sci

18:30, 04-Jul-2017

German robot maker seizes opportunity from industry revolution

By CGTN's Zhang He

The fourth industrial revolution holds plenty of promises, especially for Germany as it continues to align two national industry initiatives, Germany's "Industry 4.0" strategy, and China's"Made in China 2025" program.

Car assembly lines of today are full of robots. They now do most of the simple and repetitive jobs required to put vehicles together, making factories more efficient.

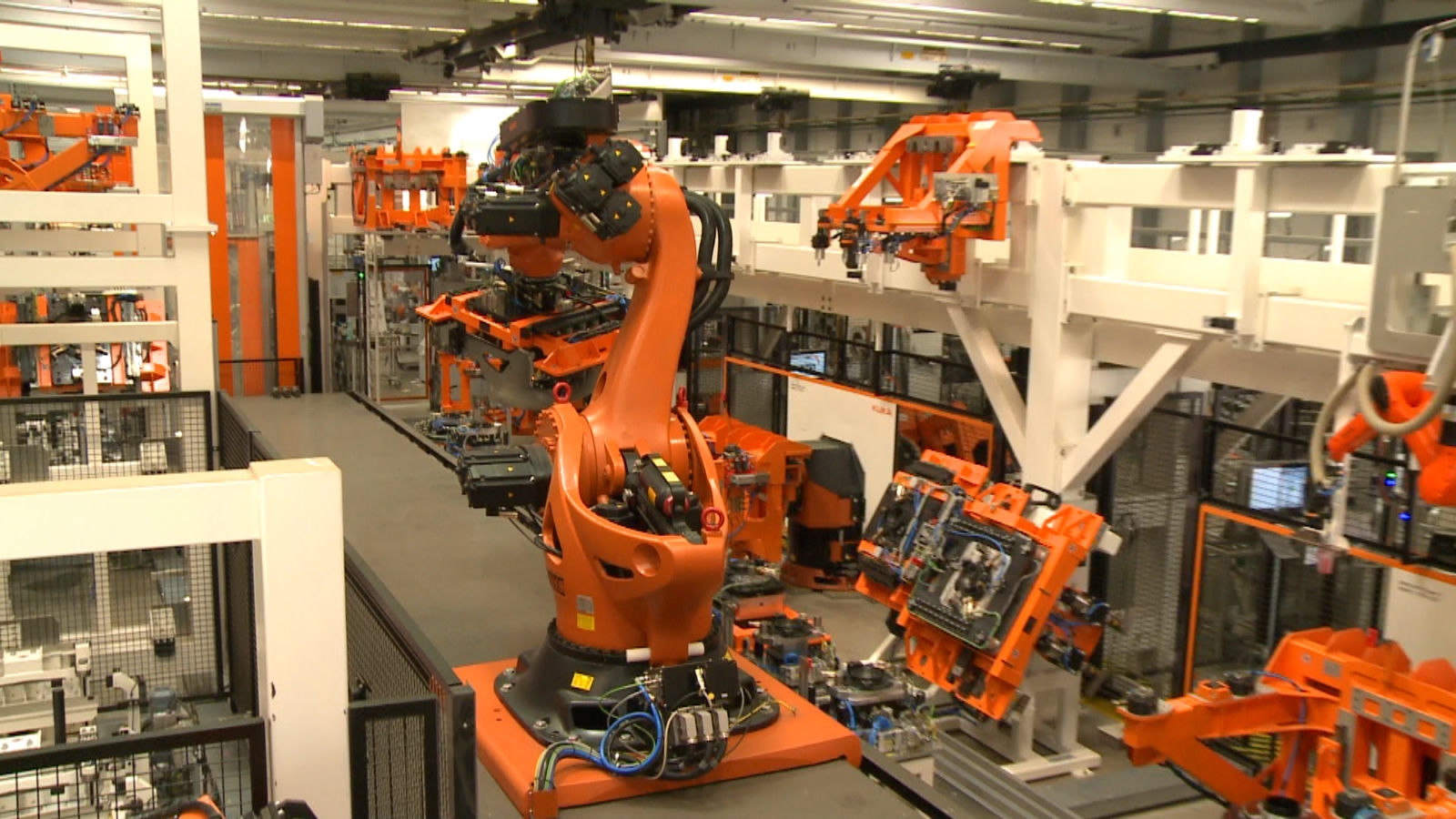

Last year, Chinese appliance manufacturer Midea acquired German robot maker KUKA. It produces around 170 different types of robots at its factory in Augsburg in south Germany. The robot will support the workers on production line and will probably complete transform the manufacturing industry in the next few decades.

KUKA’s robot factory in Augsburg, southern Germany on 28 June, 2017. /CGTN Photo

KUKA’s robot factory in Augsburg, southern Germany on 28 June, 2017. /CGTN Photo

As a key player in the Industry 4.0 strategy, KUKA rolled out a collaborative robot for industrial applications. It can work together with humans without protective fencing and also streamline its movement data to cloud storage.

”We are the first to talk about Internet of Things (IoT) and 4.0, but also do it.“ said Till Reuter, KUKA’s CEO, “We have product called KUKA Connect, in which we think we are the leaders of IoT and 4.0 in Germany. We support to connect the machine, the shop floor with the cloud. And really get the benefit of the cloud onto the shop floor for the benefit of our customers.”

Till Reuter, KUKA’s Chief Executive Officer. /CGTN Photo

Till Reuter, KUKA’s Chief Executive Officer. /CGTN Photo

China’s Midea Group, which acquired the German robot maker, was in search of opportunities to upgrade its capabilities under the “Made in China 2025” push.

“Chinese investors going into Germany or any other company become so much professional during the last 10 years doing very clear analysis," said Stefan Matz, International Business Director of Hamburg Business Development Corporation. "So refer to KUKA, refer to other small and medium-sized machinery manufactures... I think the Chinese are doing pretty well to identify where the German strong industry companies are located.”

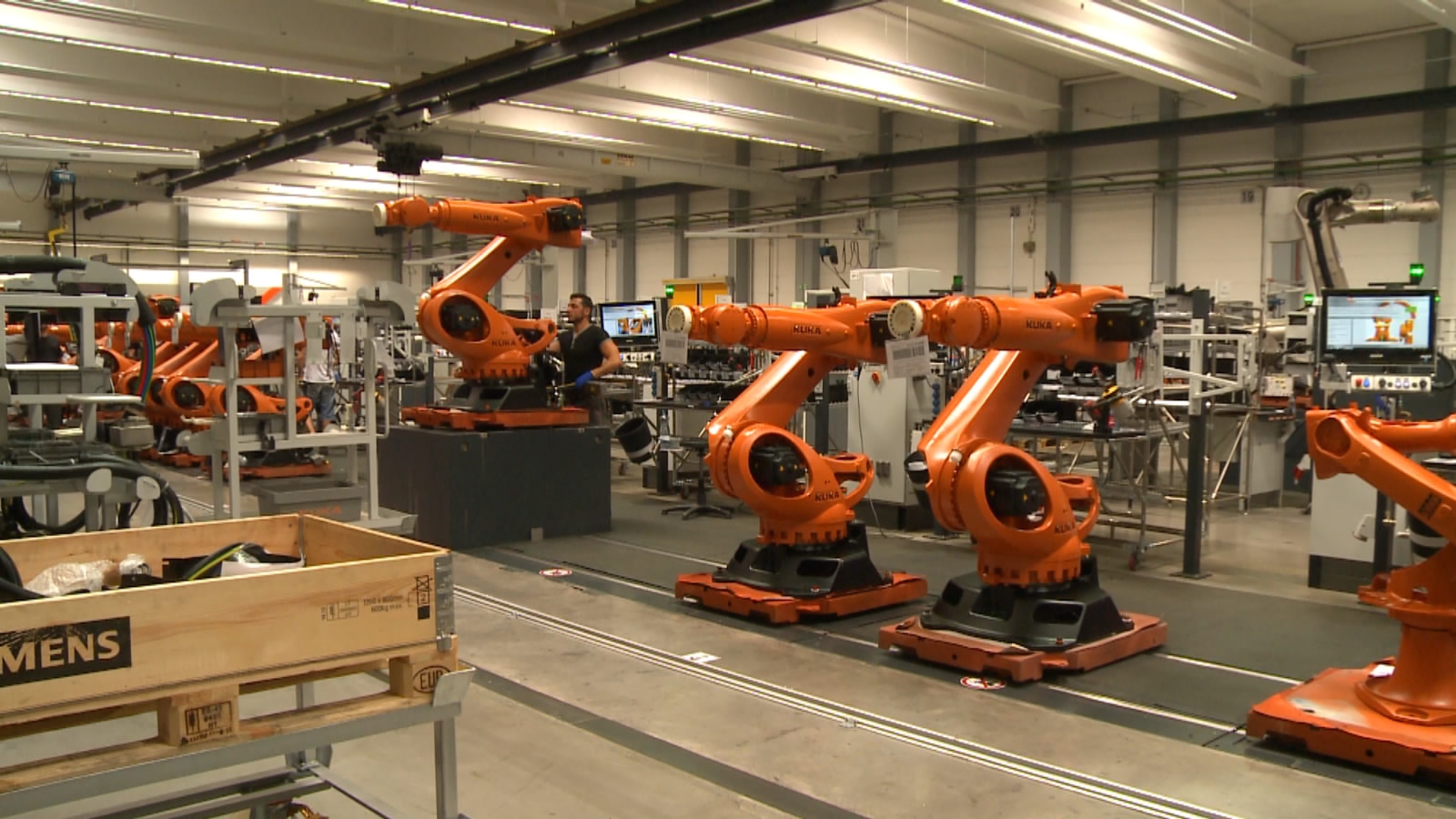

KUKA’s robot factory in Augsburg, southern Germany on 28 June, 2017./ CGTN Photo

KUKA’s robot factory in Augsburg, southern Germany on 28 June, 2017./ CGTN Photo

The takeover will help KUKA consolidate its position in the growing Chinese robot market, as it takes advantage of its experience in Germany’s 4.0 plan.

KUKA. /CGTN Photo

KUKA. /CGTN Photo

“If you look at the IoT or Germany's 4.0 agenda, and the Made in China 2025 plan, they are very similar (with) what they want to reach. I think there is a good opportunity to combine the two, reaching much more and have a bridge between German and China,” said Reuter.

7785km

SITEMAP

Copyright © 2018 CGTN. Beijing ICP prepared NO.16065310-3

Copyright © 2018 CGTN. Beijing ICP prepared NO.16065310-3