Tech & Sci

21:46, 06-Oct-2017

New test opens the way for better 2D catalysts

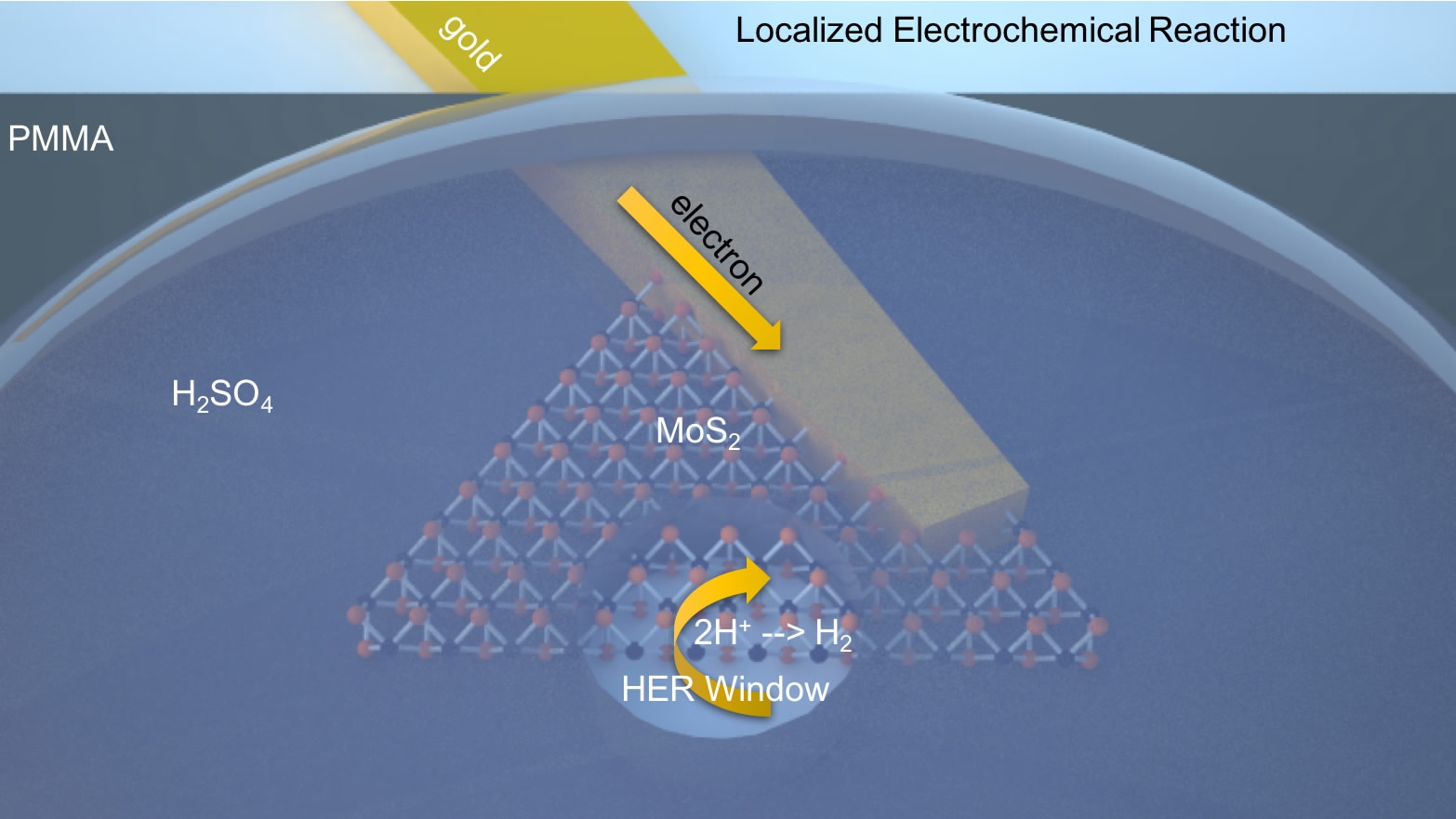

A new technique developed by US researchers allows researchers to quickly probe atom-thick materials to measure hydrogen production, and may accelerate the development of 2D materials for energy applications, such as fuel cells.

According to a news release by Rice University on Thursday, the Rice lab of materials scientist Jun Lou, with colleagues at Los Alamos National Laboratory from the state of New Mexico, developed a technique to probe through tiny "windows" created by an electron beam and measure the catalytic activity of molybdenum disulfide, a two-dimensional material that shows promise for applications that use electrocatalysis to extract hydrogen from water.

Initial tests on two variations of the material proved that most production is coming from the thin sheets' edges. Researchers already knew the edges of 2D materials are where the catalytic action is, so any information that helps maximize it is valuable, Lou said.

"We're using this new technology to identify the active sites that have been long-predicted by theory," he said. "There was some indirect proof that the edge sites are always more active than the basal planes, but now we have direct proof."

The probe-bearing microchips developed at Los Alamos and the method created by Lou and lead author Jing Zhang, a Rice postdoctoral researcher, open a pathway to fast screening of potential hydrogen evolution reaction candidates among two-dimensional materials.

The researchers reported their results this month in Advanced Materials.

(Top photo: The Rice lab uses an electron beam to drill submicron holes through an insulating layer of poly, methyl methacrylate, to probe specific areas of nanoscale flakes. /Rice University)

Source(s): Xinhua News Agency

SITEMAP

Copyright © 2018 CGTN. Beijing ICP prepared NO.16065310-3

Copyright © 2018 CGTN. Beijing ICP prepared NO.16065310-3