04:01

Editor's note: This story is part of our continuing World Factory series, which delves into the trajectory of China's economic growth amid a changing geopolitical landscape, the pandemic and a global economic recession. You can read the first, second, third, fourth, fifth, sixth and seventh stories here.

Guo Qing joined Gongyuan in late 2019. As a former deputy chief of a large state-owned enterprise who had just finished a management training program, he thought he would be promoted to an even larger company. Instead, he was appointed director of corporate responsibility at Gongyuan, a heavily indebted factory that has not produced anything in 14 years.

"I was frustrated," Guo said. "I kept asking why they sent me to a factory that only has a few dozen employees left. But as I learned more about Gongyuan's history and felt the deep affection that many still have for it, I became fascinated by it, and I know I should help preserve its legacy.”

Gongyuan, which used to make photographic film and paper, was once the pillar of China's photosensitive material industry. Founded in the 1950s when China didn't have access to foreign technology, Gongyuan created its own production line and manufactured the first black and white photographic film and paper in the country.

A front view of the office building of China's photosensitive material maker Gongyuan, in Shantou, south China's Guangdong Province, April 27, 2021. /CGTN

A front view of the office building of China's photosensitive material maker Gongyuan, in Shantou, south China's Guangdong Province, April 27, 2021. /CGTN

It also pioneered other products like printing plates and X-ray films. Given that these materials had extensive uses in the military, medical and cinema industries, the firm's capacity to produce them gradually transformed a small workshop into a production center that was seen as the pride of China's industrial sector.

However, digitization dealt a fatal blow to Gongyuan's business at the turn of the century, and the company closed its door after more than 50 years of operation.

For the last 14 years, Gongyuan has stood quietly. The workers who have been part of the celebrated journey of the company want to preserve it, and Guo's job is to spearhead the application for state recognition as an industrial heritage site.

The legacy

The exhibition hall recently set up at the site is filled with a myriad of medals commemorating the company's contribution to the country. But none of that demonstrates the spiritual value of preserving it in the way Gongyuan workers desire.

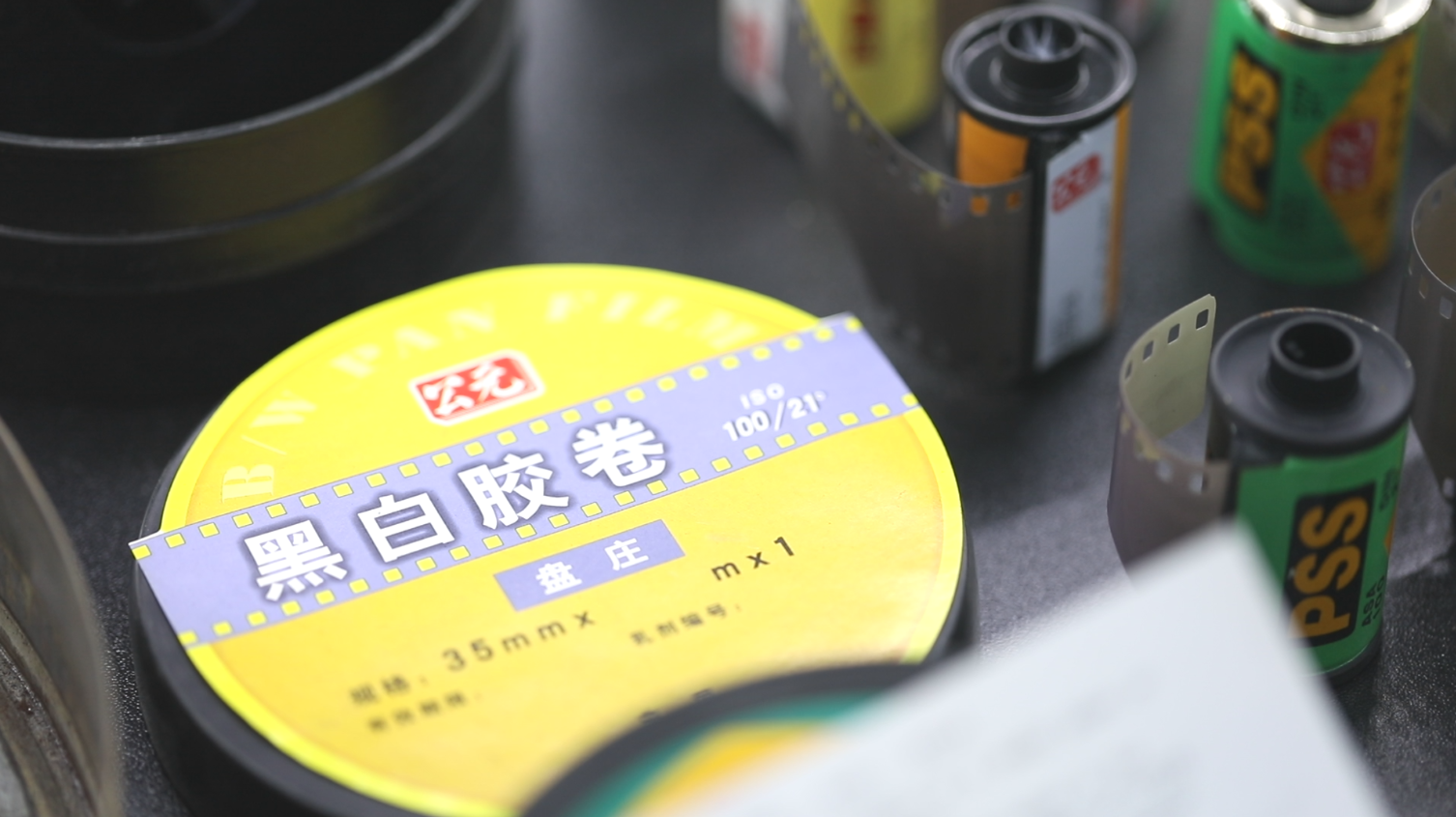

Gongyuan's black and white film lies in the company's exhibition hall, in Shantou, south China's Guangdong Province, April 27, 2021. /CGTN

Gongyuan's black and white film lies in the company's exhibition hall, in Shantou, south China's Guangdong Province, April 27, 2021. /CGTN

Xie Weiming, Party branch secretary at Gongyuan, is among those at the forefront of the effort. He joined Gongyuan as an apprentice when he was 18, regarding it as a place where he could make his mark.

Having devoted over 35 years of his life to the factory, Xie said his only mission nowadays is to secure a heritage designation for Gongyuan.

"I have witnessed Gongyuan's most thriving moments. I've also come to appreciate what it stands for. It would be my biggest regret to see this great historical site gone," he said.

A visit to the factory helps to explain why feelings are so strong. For one, the black and white production line has been well-preserved. Perhaps because the building was designed to avoid light, machines and auxiliary devices also look almost spotless. The production line exudes a strong historical flavor reminiscent of the neat and orderly manufacturing setup that existed back then.

Gongyuan brought in machinery from abroad. The machines imported from Germany cost a small fortune at the time, in Shantou, south China's Guangdong Province, April 27, 2021. /CGTN

Gongyuan brought in machinery from abroad. The machines imported from Germany cost a small fortune at the time, in Shantou, south China's Guangdong Province, April 27, 2021. /CGTN

The complexity of operating the production line and the extra steps needed to ensure that none of the finished products are contaminated are other features that stand out.

"We would not know if any of our finished products are flawed or stained with dust, not even when our buyers have received them," Xie said. "Only when the images are shown on the paper can we tell whether lapses occur during the manufacturing process. That's why we have to be extremely meticulous about everything."

A national hero

The manufacturing process started with making the chemicals needed to coat the photographic paper and film. Called photosensitizers, they give photographic film and paper the capacity to sense light.

But synthesizing the chemicals was not easy because the process required exceptionally delicate handling. Also, most of the raw materials came from a special market that was closely connected to high technology, involved national security and enjoyed monopoly status.

One can find over 100 different chemical raw materials in a small piece of film, Xie said.

Xie Weiming holds a chemical formula that was key to Gongyuan's manufacturing process, in Shantou, south China's Guangdong Province, April 27, 2021. /CGTN

Xie Weiming holds a chemical formula that was key to Gongyuan's manufacturing process, in Shantou, south China's Guangdong Province, April 27, 2021. /CGTN

"Being able to produce photographic film is like having the capacity to make rockets," Chinese historian and poet Guo Moruo once said.

At a time when the project seemed impossible, Gongyuan's founder Lin Xizhi made it happen.

Lin spent much of his childhood witnessing the Japanese occupation of his hometown and was determined to become a harbinger of the revival of China.

He once heard a foreign teacher mock the backwardness of China's industry at school. Further driven by the belief that "what foreigners can make, Chinese can make too," Lin forged ahead despite mounting difficulties.

The respect paid to Lin Xinzhi can still be felt today. Renowned sculptor Zhang Zimeng offered his free services to make this unfinished sculpture of Lin. /Courtesy of Zhang Zimeng

The respect paid to Lin Xinzhi can still be felt today. Renowned sculptor Zhang Zimeng offered his free services to make this unfinished sculpture of Lin. /Courtesy of Zhang Zimeng

In 1949, he opened the Gongyuan chemical lab in his hometown. But it was short of quality equipment. Relevant study materials were also scarce, and sourcing them was extremely difficult. He made progress only through countless all-nighters researching and experimenting in the lab.

In October 1952, the first Chinese-made black and white photographic paper was born.

"Lin's spirit is particularly what we want to perpetuate today," Xie said. "We are now facing an international environment that's similar to Lin's times. Technological blockades imposed upon China can curb our economic development, so we need more people like Lin to continue their path on innovation."

Video editor: Wang Zengzheng

Writer: Li Ruikang

Voiceover: Sim Sim Wissgott

Cover image designer: Chen Yuyang